Sourcing and Selecting Raw Materials for Frozen Fish Processing

By. Najih - 02 Jul 2024.jpg)

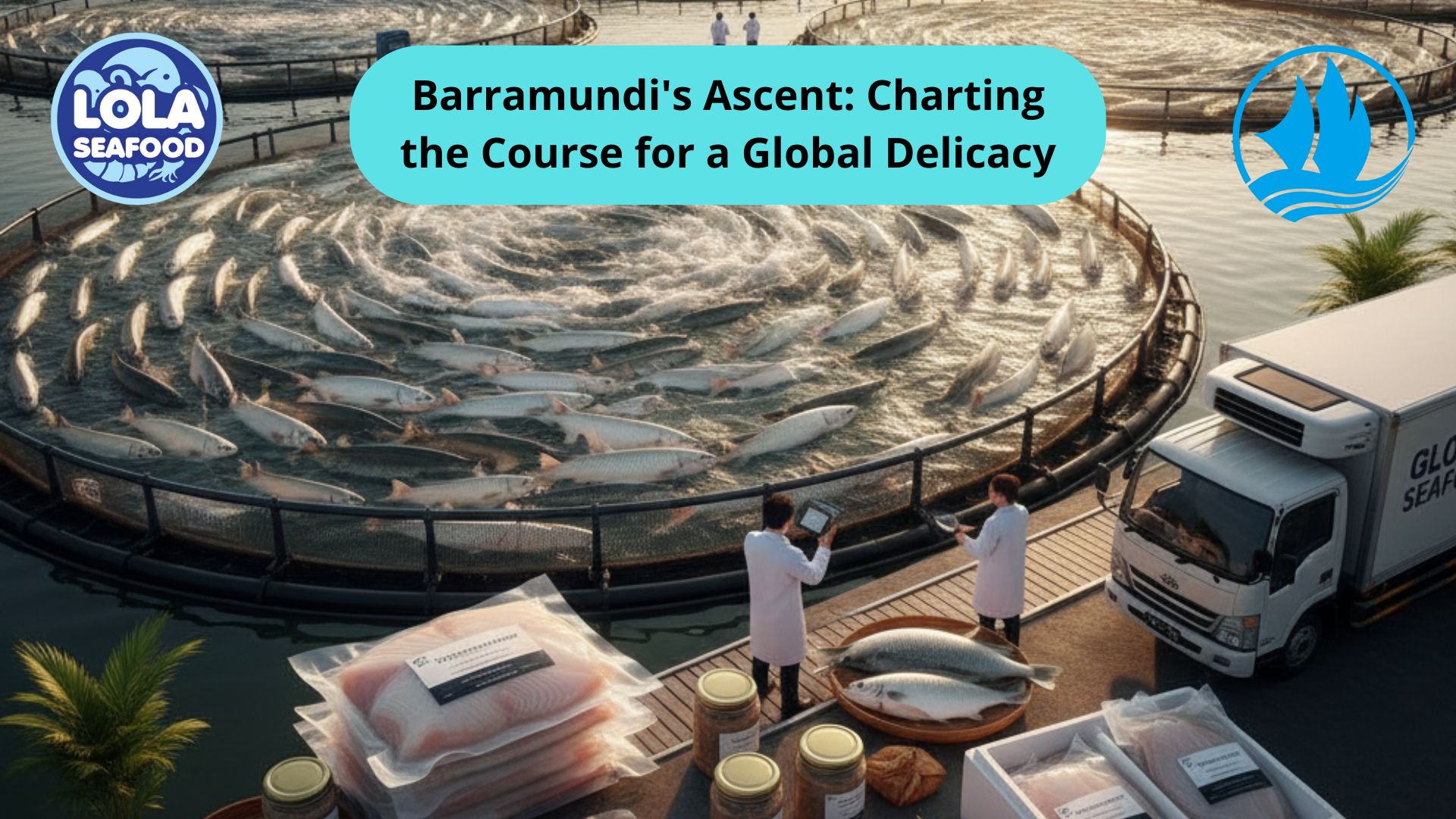

Globalization has transformed the sourcing landscape for frozen fish processors. Companies must navigate international markets to secure a consistent supply of high-quality raw fish. Strategies include establishing reliable supplier relationships, diversifying sourcing regions to mitigate risks, and leveraging market intelligence to capitalize on seasonal variations and price fluctuations.

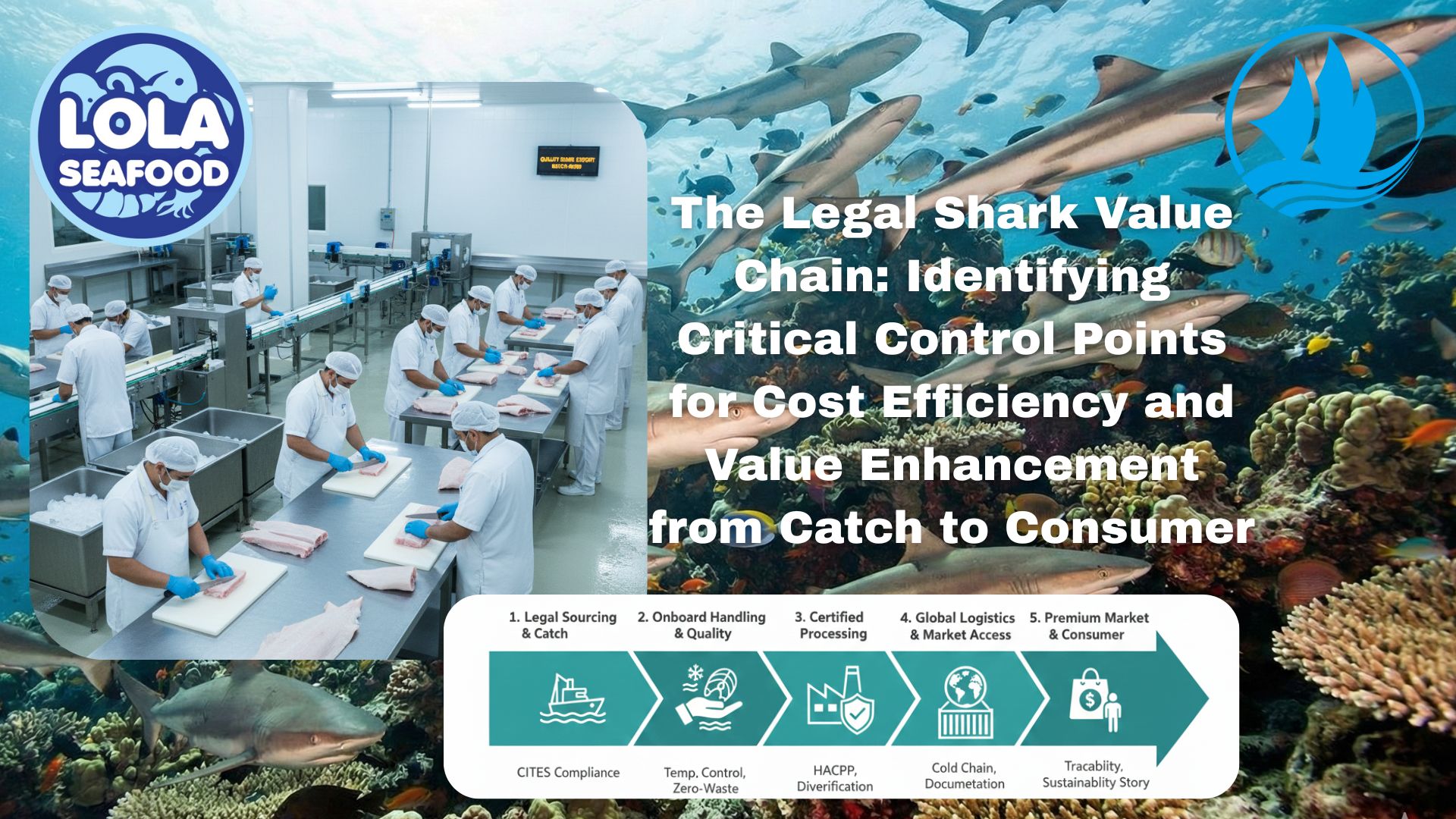

The foundation of successful raw material sourcing lies in adherence to rigorous quality standards. Processors prioritize freshness, species authenticity, size uniformity, and sustainability certifications such as MSC (Marine Stewardship Council) or ASC (Aquaculture Stewardship Council). These criteria ensure that the raw fish not only meets regulatory requirements but also aligns with consumer preferences for ethical and environmentally responsible products.

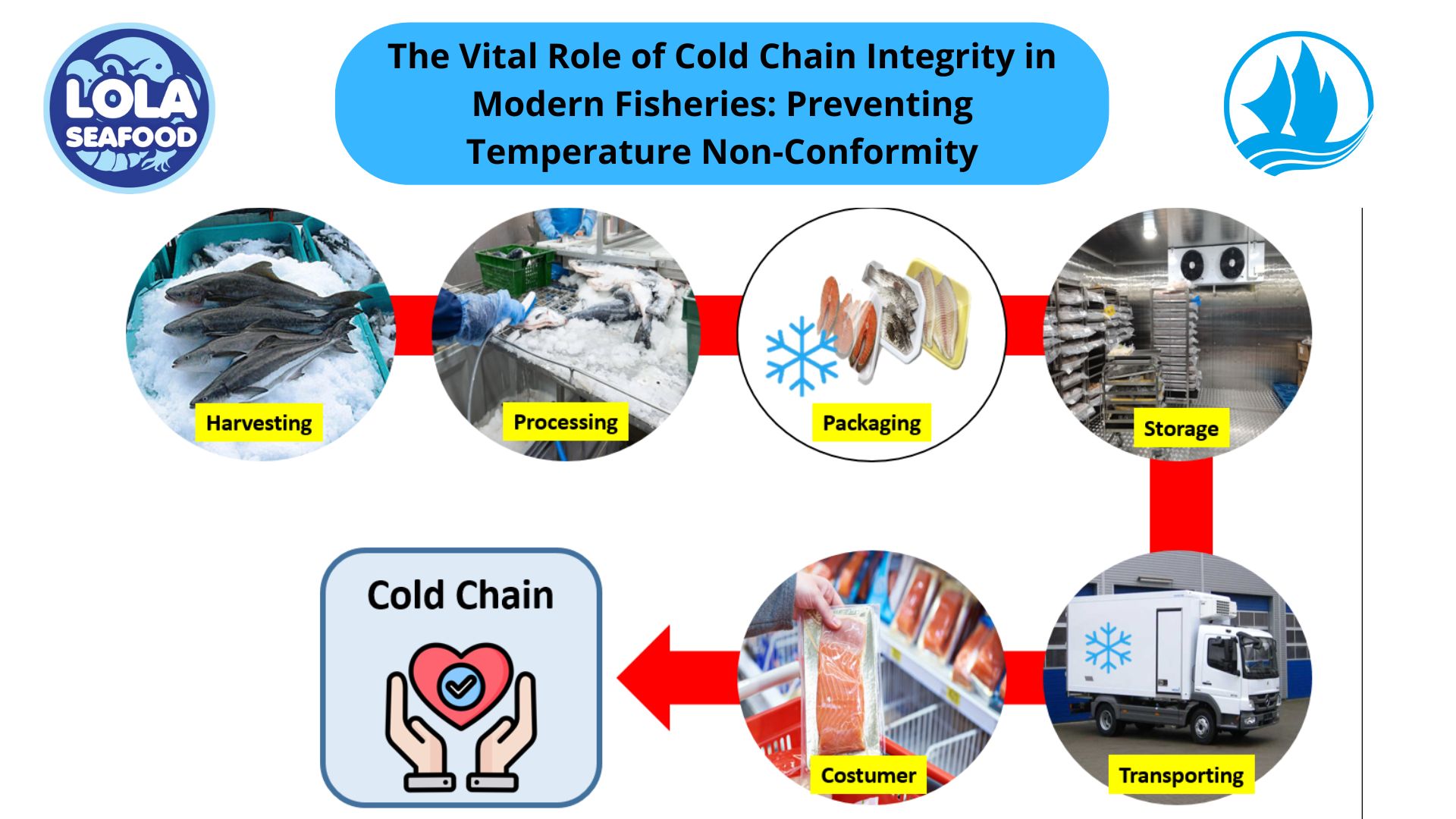

Efficient supply chain management is crucial to maintaining the integrity of raw materials from catch to processing. This involves meticulous planning of logistics, optimizing transportation routes, and implementing robust storage and handling practices. Technologies like cold chain monitoring systems and traceability software play a pivotal role in safeguarding product quality and compliance throughout the supply chain.

The frozen fish industry operates within a complex regulatory framework aimed at ensuring food safety and traceability. Processors must adhere to stringent hygiene standards, conduct regular audits of suppliers, and implement comprehensive risk management protocols to mitigate potential hazards such as contamination or adulteration. Compliance with international regulations, including FDA and EU standards, is non-negotiable to maintain market access and consumer trust.

As environmental sustainability becomes increasingly important to consumers, processors are embracing sustainable sourcing practices. This includes supporting fisheries and aquaculture operations that prioritize ecosystem health, minimize bycatch, and uphold fair labor practices. Certification programs and traceability initiatives provide transparency and assurance that raw materials are sourced responsibly, contributing to long-term industry viability.

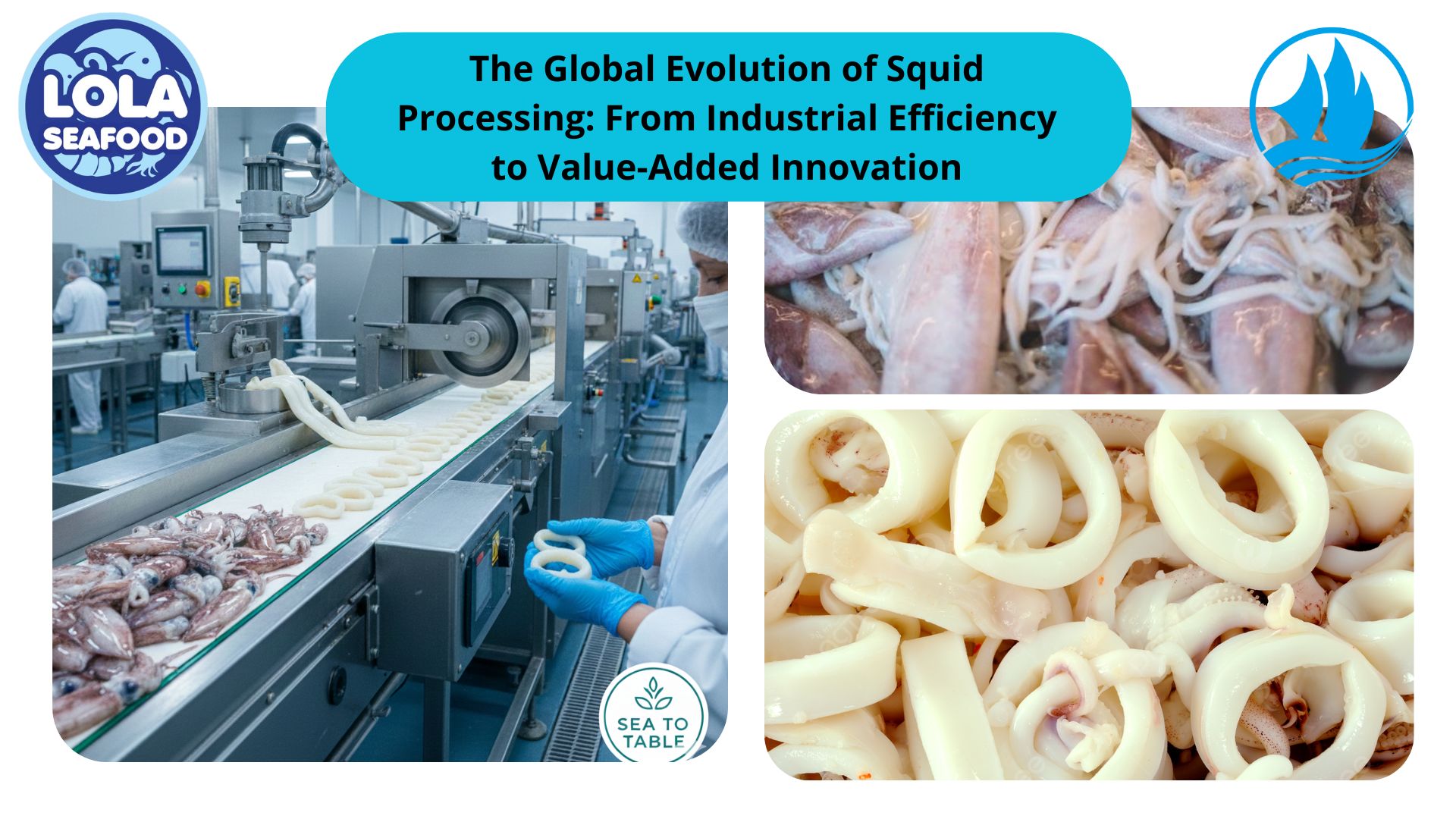

Advancements in technology continue to revolutionize raw material sourcing and processing efficiencies. Automated fish grading systems, AI-driven predictive analytics for demand forecasting, and blockchain-based traceability platforms are transforming how processors manage inventory, optimize production schedules, and ensure product quality consistency. These innovations not only enhance operational efficiencies but also enable processors to meet evolving consumer demands for transparency and product traceability.

Understanding market trends and consumer preferences is essential for strategic decision-making in raw material sourcing. Processors monitor shifts in consumer demand for specific fish species, organic and natural products, and ethical sourcing practices. By aligning sourcing strategies with market trends, processors can capitalize on opportunities and differentiate their products in a competitive marketplace.

The frozen fish processing industry faces challenges such as fluctuating raw material costs, supply chain disruptions, and geopolitical uncertainties. Solutions include fostering strategic partnerships with suppliers, investing in alternative sourcing regions, and adopting agile supply chain practices to respond swiftly to market dynamics. Collaboration across the industry and proactive risk management strategies are essential for overcoming these challenges and sustaining business resilience.

.jpg)

The Impact of HACCP-Based Integrated Quality Management Programs on the Quality and Competitiveness of Fresh Demersal Fish Products

and Employee Productivity on the Demersal Fish Processing Floor.jpg)

.jpg)