The Methodology for Food Testing

By. Najih - 24 Jul 2024.jpg)

Food testing is critical for ensuring food safety and quality. It helps in identifying harmful contaminants in food that can cause foodborne illnesses, allergies, or other health problems. Food testing helps in identifying the source of contamination and taking corrective measures to prevent the spread of the contamination. In addition, food product testing brings clarity regarding the composition, enabling consumers to make better food choices and trust the food manufacturing firms. Food testing also makes sure that novel food components and additives are standardised and used at recommended levels. Food product testing has been gaining importance recently and must be tested at every stage, from ingredients to the final product, so that the final product has the best quality.

Before conducting any tests, clearly defining the testing process’s objectives and goals is crucial. This involves identifying the specific characteristics of the food product that must be tested and determining the type of testing required. Food samples are collected and prepared for testing. This may involve cutting, grinding, or homogenising the sample with the help of homogenisers, depending on the type of test being conducted. The typical sample types for food product testing are- raw materials, process samples control, finished product, competitor sample and complaint sample.

Food testing can be performed using various methods, depending on the type of contaminant being analyzed. Some of the commonly used methods for food testing are:

- Microbiological testing: Microbiological testing is used to detect the presence of microorganisms in food, such as bacteria, viruses, and fungi.

- Chemical testing: Chemical testing is used to identify the presence of harmful chemicals in food, such as pesticides, heavy metals, and food additives. Chemical testing is also used to determine the nutrient content of food products.

- Physical testing: Physical testing is used to identify the physical properties of food products, such as texture, colour, and appearance.

Data is collected during testing and analysed to determine whether the food product meets the desired specifications. This may involve statistical analysis, comparing the test results to industry standards, or using expert judgment to evaluate the results. The results of the tests are reported and interpreted to determine whether the food product is acceptable for distribution or sale. Corrective actions may be recommended if the product does not meet the desired specifications. Once a food product has been tested and approved, it may be necessary to periodically validate and verify that the product continues to meet the desired specifications. This involves conducting ongoing testing to ensure the product remains safe, high-quality, and meets consumer expectations.

.jpg)

The Impact of HACCP-Based Integrated Quality Management Programs on the Quality and Competitiveness of Fresh Demersal Fish Products

and Employee Productivity on the Demersal Fish Processing Floor.jpg)

The Correlation Between Occupational Health and Safety (OHS) and Employee Productivity on the Demersal Fish Processing Floor

Human Resource Management Challenges and Training Needs in Implementing HACCP Quality Standards within the Fish Processing Industry

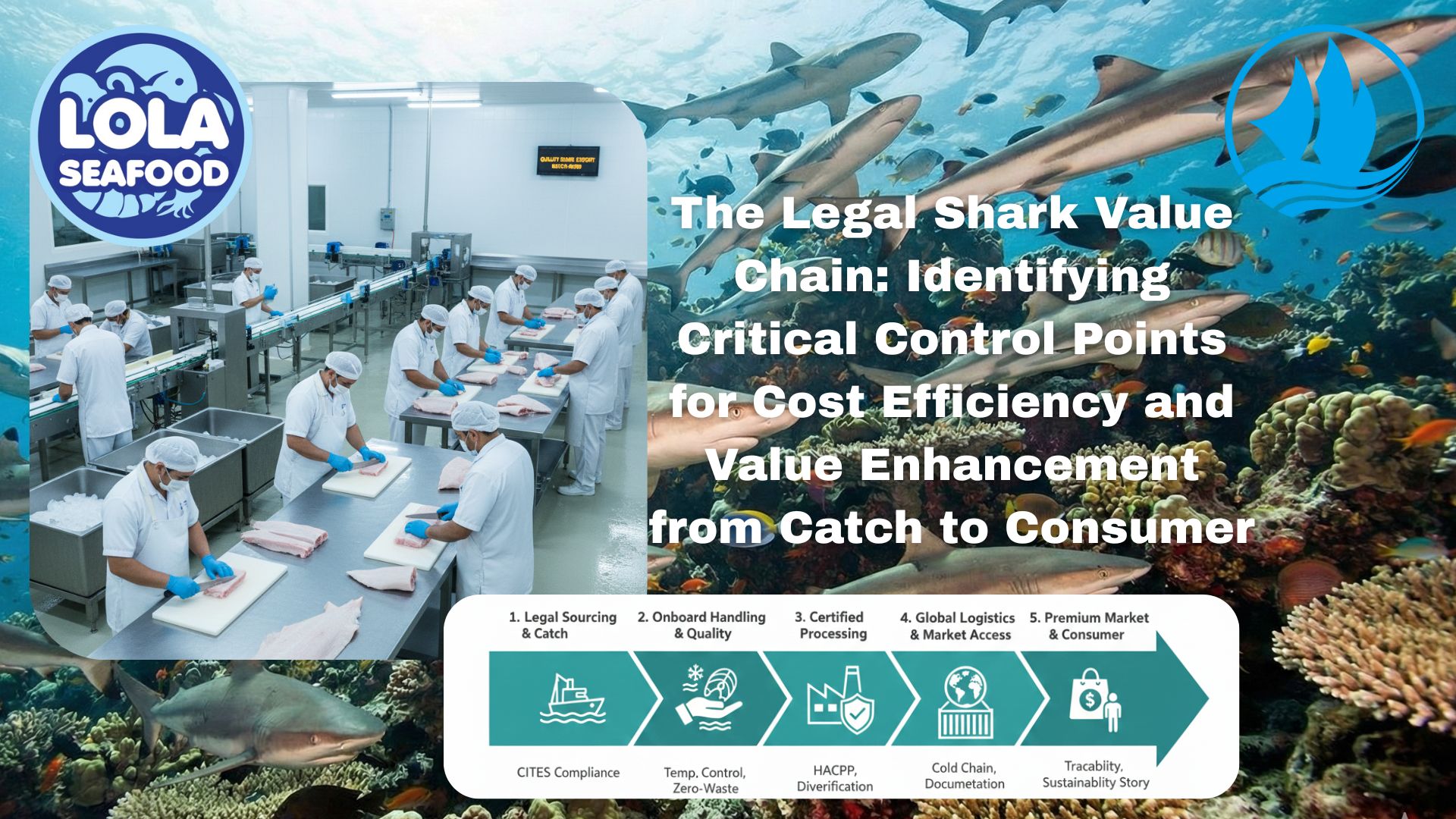

The Legal Shark Value Chain: Identifying Critical Control Points for Cost Efficiency and Value Enhancement from Catch to Consumer

.jpg)

in Meeting Global Protein Demand Sustainably.jpg)