Effective Methods for Tracking Batch, Lot, and Expiry Dates

By. Najih - 31 Jul 2024.jpg)

Batch defines a specific quantity of goods which have the same properties, that are processed together in a contiguous process. The batch number consists of a combination of letters or numbers and clearly identifies a specific batch. This number allows your customers to tell at a glance if they are affected by a recall. Tracking batch, lot, and expiry dates is an essential aspect of inventory management in many industries, especially the food, pharmaceutical, and cosmetic industries. The accurate tracking of these dates ensures that products are safe for consumption and use, and it also helps to prevent product recalls and waste.

Here are some practical methods for tracking batch, lot, and expiry dates:

- Warehouse Management System (WMS):

Implementing a warehouse management systemcan significantly enhance the tracking of batch numbers, lot numbers, and expiry dates. A WMS integrates various technologies into one comprehensive system, including barcode scanning, RFID, and FIFO methods. It provides accurate real-time data on inventory levels, product locations, and expiry dates. With a WMS, businesses can automate many aspects of inventory management, reducing the risk of human error and improving overall efficiency.

- First-In, First-Out (FIFO) Method:

The FIFO methode is a fundamental principle in inventory management, particularly relevant for products with expiration dates. By ensuring that the oldest stock (first-in) is sold or used before the newer stock (first-out), businesses can significantly reduce the risk of having to dispose of expired goods.

- Barcode or QR Code Scanning:

Barcode or QR Code Scanning are practical tools for managing inventory, including tracking batch, lot, and expiry dates. Attaching these codes to products or batches allows quick scanning to retrieve manufacturing and expiration details. Implementing a barcode or QR code system in your inventory management process ensures that products are easily tracked and any expired or nearly expired products are identified swiftly.

- Lot Control:

Lot control is about assigning a unique identifier to each batch of products. This practice is crucial for traceability and recall management. In the event of a product recall or quality issue, having a robust lot control system allows businesses to quickly identify and isolate affected products, minimising risk to consumers and the business.

.jpg)

The Impact of HACCP-Based Integrated Quality Management Programs on the Quality and Competitiveness of Fresh Demersal Fish Products

and Employee Productivity on the Demersal Fish Processing Floor.jpg)

The Correlation Between Occupational Health and Safety (OHS) and Employee Productivity on the Demersal Fish Processing Floor

Human Resource Management Challenges and Training Needs in Implementing HACCP Quality Standards within the Fish Processing Industry

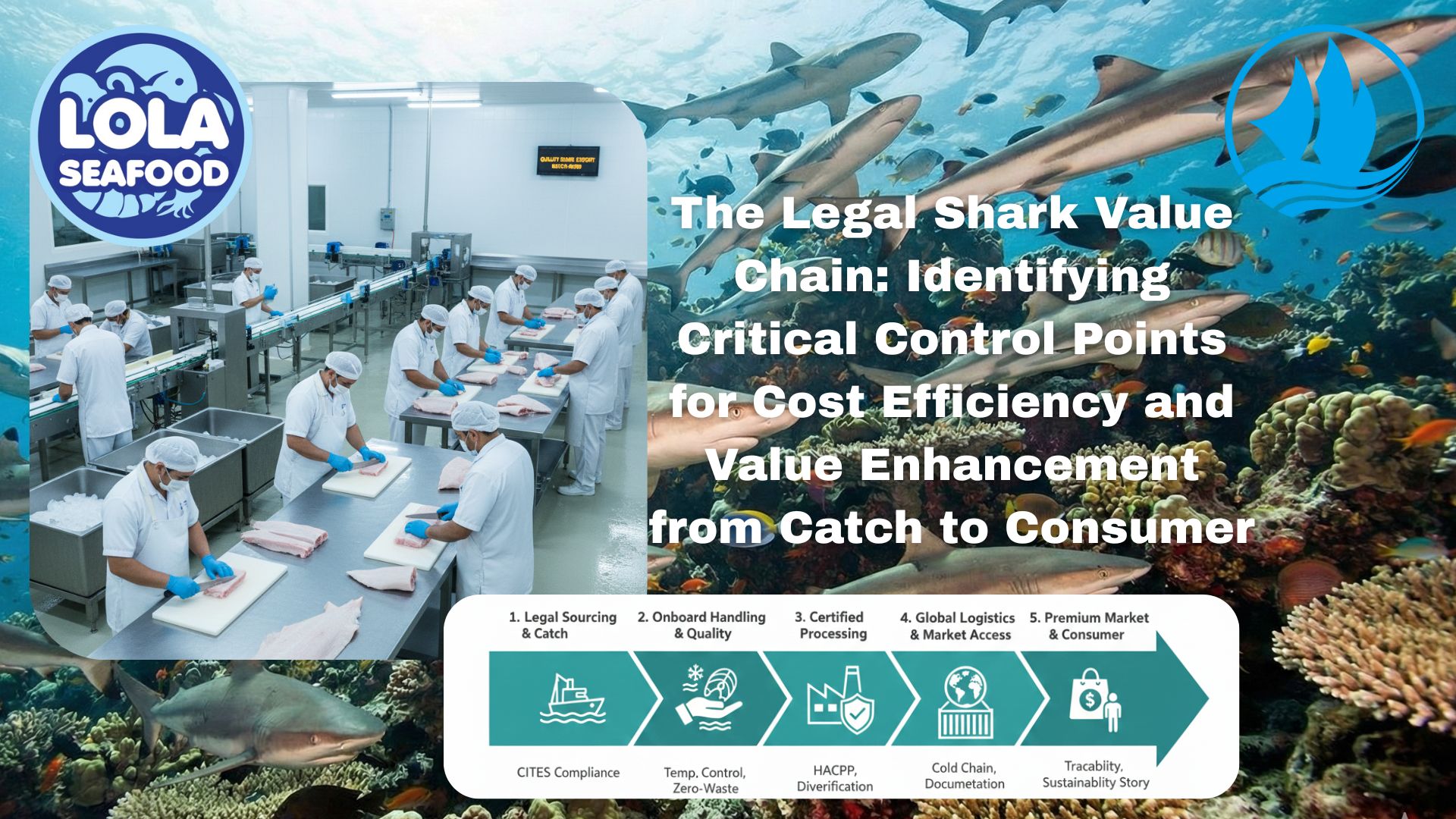

The Legal Shark Value Chain: Identifying Critical Control Points for Cost Efficiency and Value Enhancement from Catch to Consumer

.jpg)

in Meeting Global Protein Demand Sustainably.jpg)