Stainless Steel for Food Processing Equipment

By. Najih - 22 Aug 2024

The food processing industry must meet strict standards and regulations for health and safety. As more and more facilities are implementing automated machinery and components for faster production, this equipment must be constructed from food-safe materials and finishes.

Food-grade stainless steel offers an optimal material choice for the food industry. Available in various grades, the many beneficial properties and features of stainless steel ensure that all food safety and hygiene standards are met, making it ideal for a wide range of food applications.

Stainless steel refers to specific iron-based alloys with a minimum of 11% chromium. The alloy includes other metals, specifically nickel, and other elements like carbon. It’s the specific, and varied, elemental makeup that gives stainless steel the properties that make it valuable in multiple industries, particularly those where the metal will be exposed to harsh or difficult environmental situations. Stainless steel is a popular material choice for food handling applications for a multitude of reasons. Not only can the material withstand harsh temperatures, but its protective oxide layer protects against the formation of rust that could lead to food contamination. One of the most important attributes of food-grade stainless steel is that it contains no dangerous chemicals that could transfer into foods. Other features and benefits that make stainless steel a good choice for the food industry include:

- Great corrosion resistance

- Extreme strength

- Ease of cleaning

- Non-reactive surface

- Low maintenance costs

- Impermeable surface to prevent contamination

- Available in various finishes

- Chemical and bacterial neutrality

- Made to handle frequent cleanings with harsh detergents

- Does not retain or transfer food smells

Effective cleaning is essential in maintaining the integrity of the process and in prevention of corrosion. The choice of cleaning method and the frequency of its application depends on the nature of the process, the food being processed, the deposits formed, hygiene requirements etc.

The cleaning methods listed are suitable for stainless steel equipment.

- Water and Steam

- Mechanical Scrubbing

- Scouring Powder and Detergents

- Alkaline Solutions

- Organic Solvents

- Nitric Acid

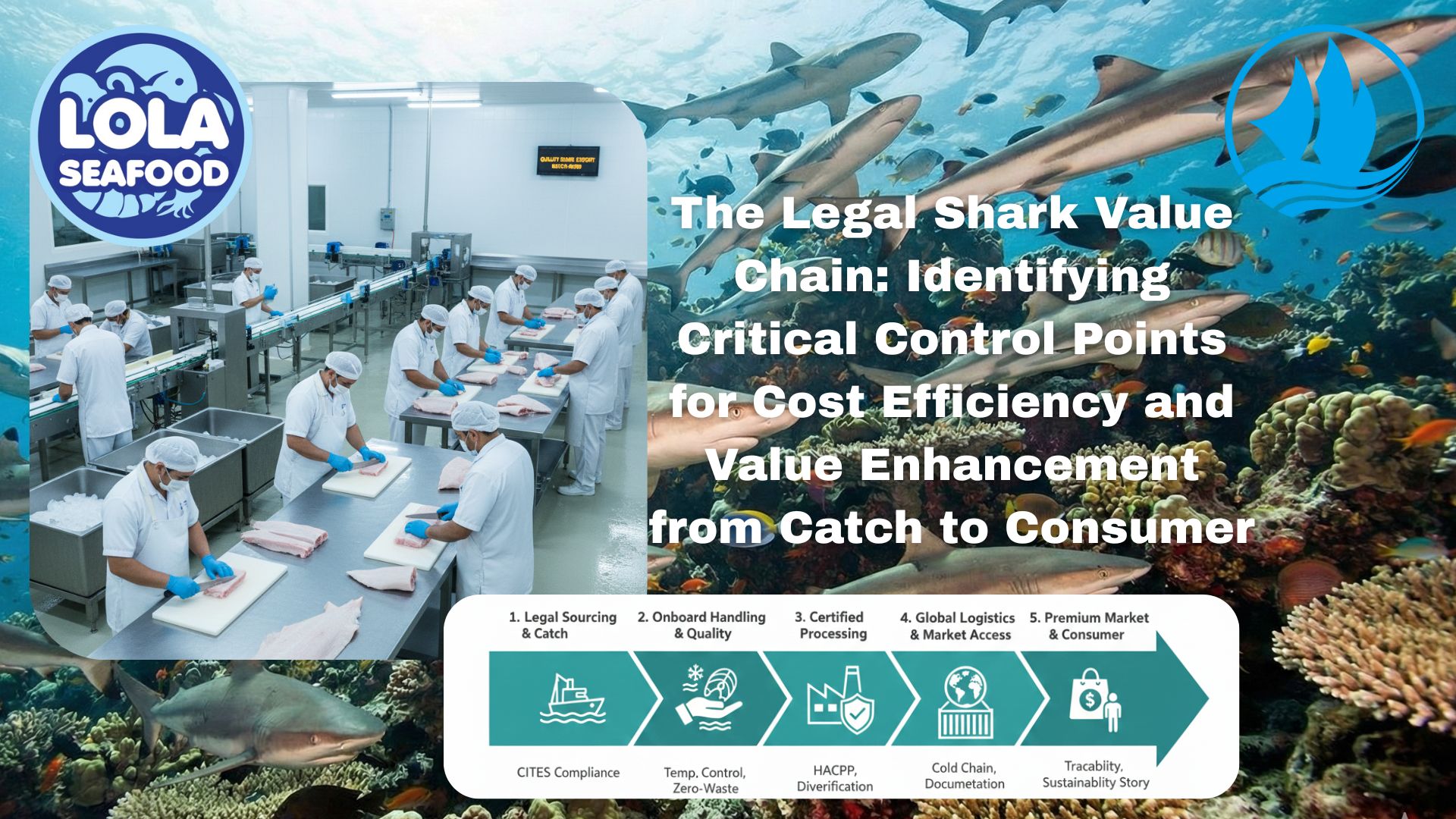

The Legal Shark Value Chain: Identifying Critical Control Points for Cost Efficiency and Value Enhancement from Catch to Consumer

Global Trust Across Three Segments: How the HACCP System Ensures Premium Quality for Demersal, Pelagic Fish, and Legal Shark Product Utilization

.jpg)

Green Investment, Profitable Harvest: How Sustainability Practices Reduce Operating Costs in Fish Fillet Processing Plants (Skin-On and Skin-Less)

in Meeting Global Protein Demand Sustainably.jpg)