Latest Innovations in Fisheries Processing

By. Najih - 11 Sep 2024.jpg)

The fisheries industry is evolving rapidly, driven by innovations that enhance the quality, efficiency, and sustainability of seafood processing. These advancements are crucial for meeting the growing global demand for seafood while addressing environmental and health concerns. This article explores the latest innovations in fisheries processing that are shaping the future of this vital industry.

1. Automated Processing Systems

Automation has revolutionized fisheries processing by increasing efficiency and reducing labor costs. Advanced automated systems now handle tasks such as sorting, filleting, and packaging with remarkable precision. These systems utilize robotics and artificial intelligence to improve consistency and reduce human error. Automated processing not only speeds up production but also enhances the quality of seafood by minimizing handling and contamination.

2. Blockchain Technology

Blockchain technology is transforming the seafood supply chain by providing transparency and traceability. This technology allows for the real-time tracking of seafood from the point of harvest to the consumer. By recording every transaction and movement on an immutable ledger, blockchain helps in ensuring the authenticity of seafood products and reduces the risk of fraud. This innovation is crucial for improving food safety and building consumer trust.

3. Sustainable Processing Practices

Sustainability is a major focus in modern fisheries processing. Innovations such as energy-efficient processing equipment, waste reduction technologies, and by-product utilization are helping to minimize the environmental impact of seafood processing. For example, waste from fish processing can be repurposed into valuable products like fishmeal and omega-3 supplements. These practices not only support environmental conservation but also contribute to a circular economy within the seafood industry.

4. High-Pressure Processing (HPP)

High-Pressure Processing (HPP) is an advanced non-thermal technology that enhances seafood safety and shelf life. HPP involves subjecting seafood to high pressure, which inactivates pathogens and extends the product’s freshness without the need for heat. This method preserves the taste, texture, and nutritional value of seafood while improving its safety profile. HPP is gaining popularity for its ability to deliver high-quality products with minimal impact on the environment.

5. Smart Packaging

Smart packaging is an innovation that integrates technology into packaging materials to monitor and maintain the quality of seafood. Features like time-temperature indicators and freshness sensors provide real-time information about the condition of the product. These smart solutions help in ensuring that seafood remains within optimal storage conditions and reduces the risk of spoilage. Additionally, smart packaging can enhance consumer confidence by providing transparent information about product quality.

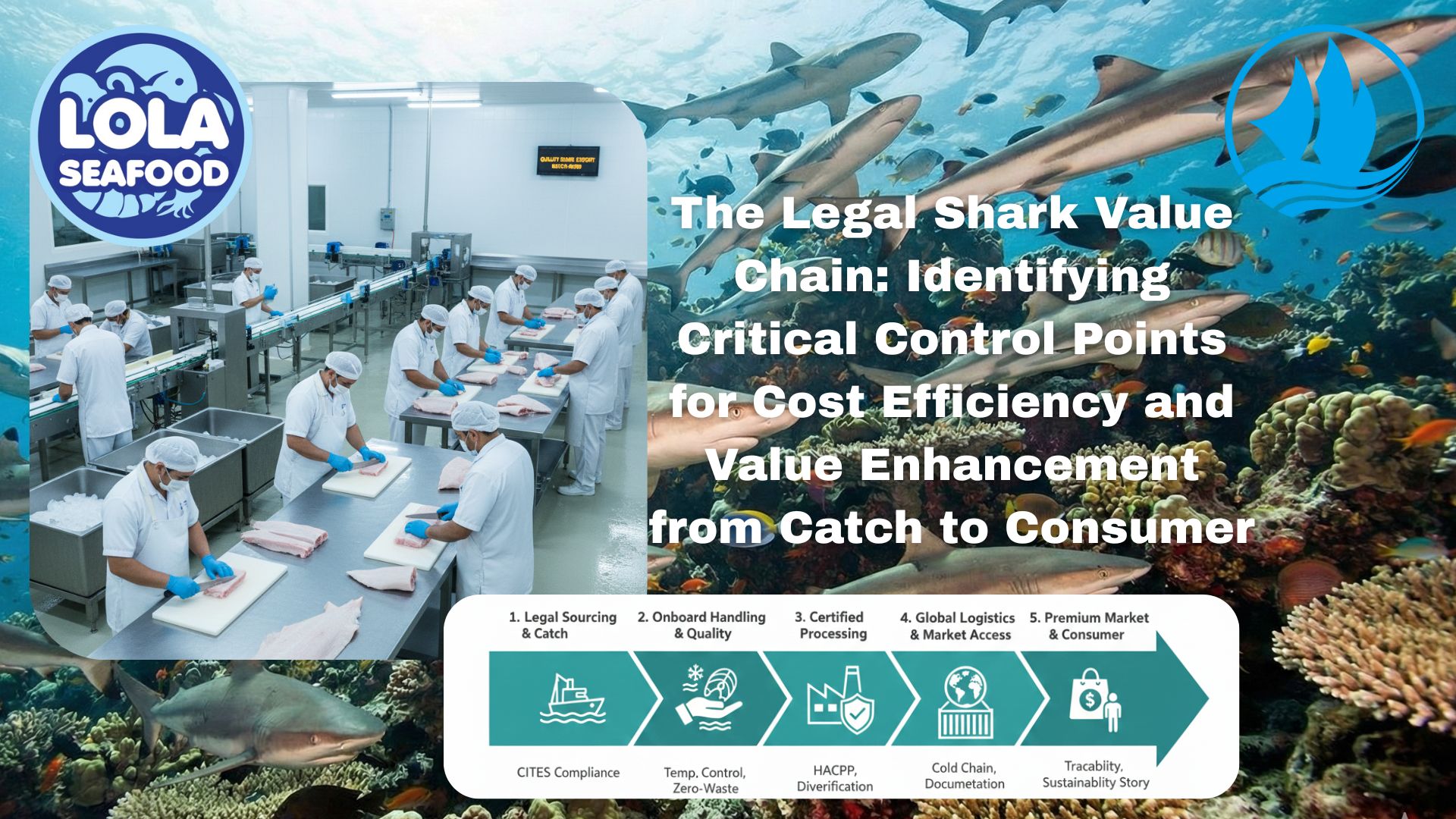

The Legal Shark Value Chain: Identifying Critical Control Points for Cost Efficiency and Value Enhancement from Catch to Consumer

Global Trust Across Three Segments: How the HACCP System Ensures Premium Quality for Demersal, Pelagic Fish, and Legal Shark Product Utilization

.jpg)

Green Investment, Profitable Harvest: How Sustainability Practices Reduce Operating Costs in Fish Fillet Processing Plants (Skin-On and Skin-Less)

in Meeting Global Protein Demand Sustainably.jpg)