Understanding Good Manufacturing Practices in Fisheries

By. Najih - 17 Sep 2024

Good Manufacturing Practices (GMP) are essential for ensuring the safety, quality, and compliance of seafood products. In the fisheries industry, adhering to GMP helps maintain high standards from catch to consumer. This article provides an overview of GMP in fisheries and their importance in delivering safe and high-quality seafood.

1. Overview of GMP in Fisheries

Good Manufacturing Practices encompass a set of guidelines and procedures aimed at ensuring that seafood products are consistently produced and controlled to meet quality standards. GMP in fisheries includes practices related to hygiene, equipment, handling, and documentation. These practices are crucial for preventing contamination and ensuring that seafood is safe for consumption.

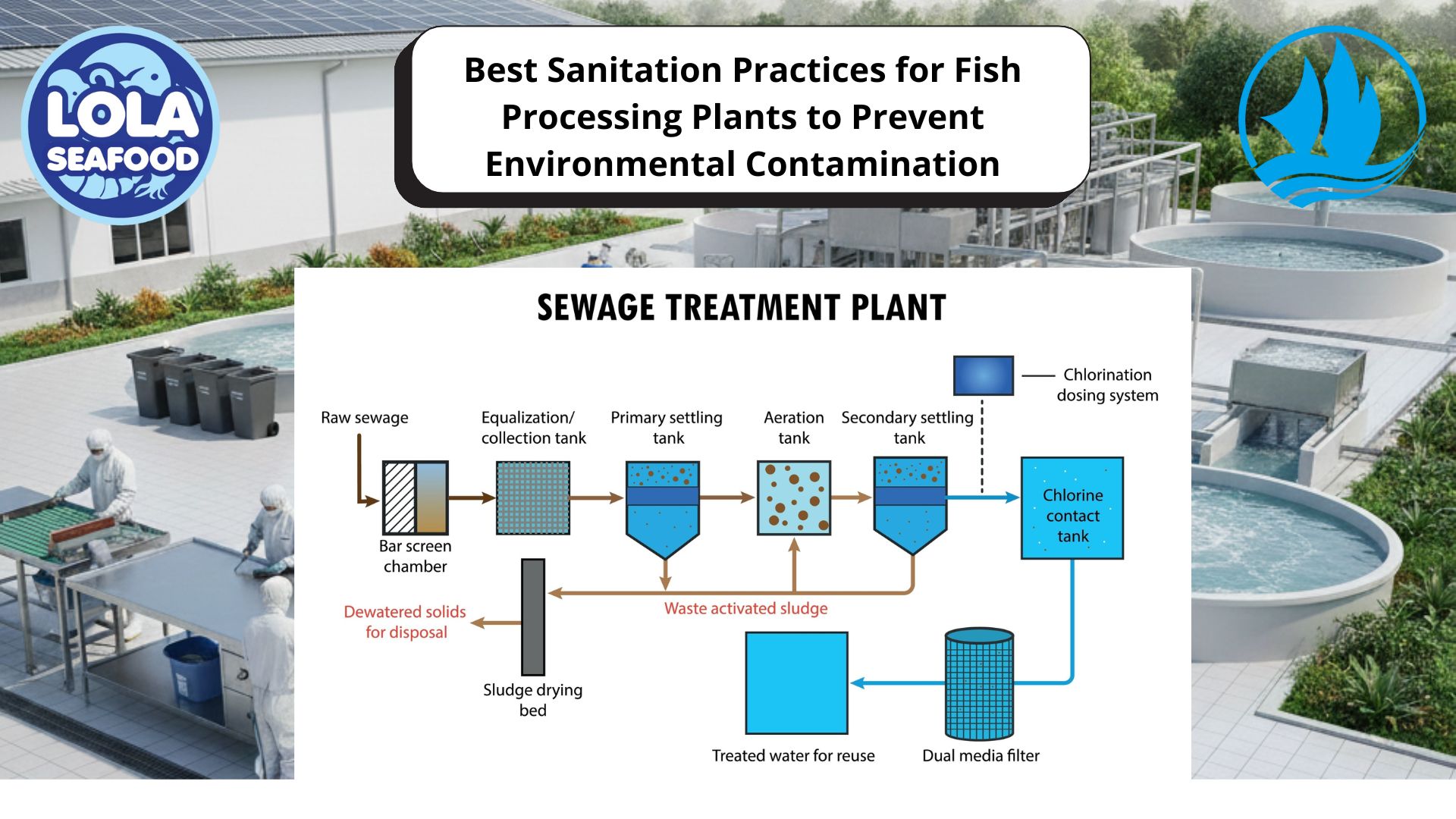

2. Hygiene and Sanitation

Hygiene is a cornerstone of GMP in fisheries. This involves maintaining clean and sanitary conditions throughout the processing and handling stages. Facilities must have rigorous cleaning protocols for equipment and work areas to prevent cross-contamination. Personal hygiene practices, such as hand washing and proper use of protective clothing, are also critical to minimizing risks.

3. Equipment and Facility Maintenance

Proper maintenance of equipment and facilities is vital to GMP. Equipment should be regularly inspected, cleaned, and maintained to ensure it functions correctly and does not pose a contamination risk. Facilities must be designed to facilitate effective cleaning and to prevent any conditions that could lead to contamination.

4. Handling and Storage

Handling and storage practices are crucial in GMP to maintain seafood quality. Fish should be handled carefully to prevent physical damage and contamination. Proper storage conditions, including temperature control, are essential to preserving freshness and preventing spoilage.

5. Documentation and Record-Keeping

Accurate documentation and record-keeping are integral to GMP. Records should detail all aspects of the production process, including sourcing, processing, and quality control measures. This documentation ensures traceability and accountability, helping to address any issues that arise and demonstrating compliance with industry standards.

6. Training and Compliance

Regular training for staff is essential to ensure that all personnel are aware of and adhere to GMP standards. Compliance with regulations and continuous improvement of practices contribute to the overall safety and quality of seafood products.

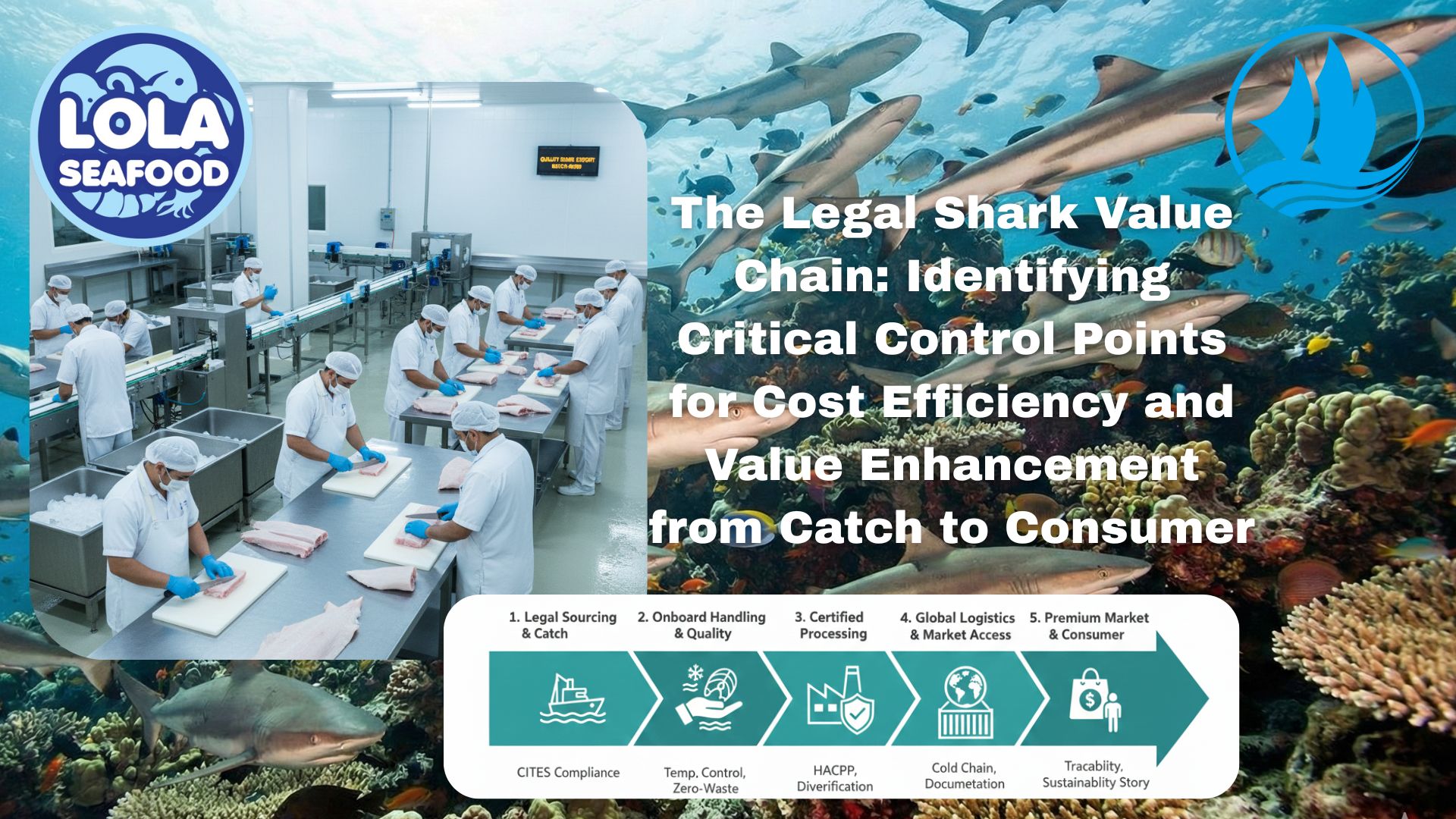

The Legal Shark Value Chain: Identifying Critical Control Points for Cost Efficiency and Value Enhancement from Catch to Consumer

Global Trust Across Three Segments: How the HACCP System Ensures Premium Quality for Demersal, Pelagic Fish, and Legal Shark Product Utilization

.jpg)

Green Investment, Profitable Harvest: How Sustainability Practices Reduce Operating Costs in Fish Fillet Processing Plants (Skin-On and Skin-Less)

in Meeting Global Protein Demand Sustainably.jpg)