The Reason For Thawing Frozen Fish Must be Hygienic

By. Najih - 09 Oct 2024

Quality fish defrosting is an essential step in fish processing. Defrosting also called is the process of transitioning a frozen product to its unfrozen state. Frozen fish is allowed to defrost in the correct manner, the quality of the fish will be preserved. It will keep its natural texture, flavour, and appearance, which will keep it appealing to customers even after the defrosting process is complete. It is important to follow the proper defrosting methods and handle fish with care to ensure that it remains safe, healthy, and delicious for consumers.

Nutritional Value :

These vital nutrients might be lost if the defrosting process is not carried out correctly. The nutritional value of fish can be preserved through proper defrosting, which ensures that consumers receive the full range of health benefits that are possible from the foods they consume.

Avoiding Bacterial Growth :

Defrost at room temperature or in warm water can create an environment that is conducive to the growth of bacteria, which can result in foodborne illnesses. Methods of defrosting that are of high quality, such as defrosting with the defrosting system, can help prevent the growth of bacteria and reduce the likelihood of foodborne illnesses.

Water and Air Defrosting :

There are two main ways how to defrost or thaw the fish products and that is air and water technologies.

- Water Thawing : allows for control over factors such as water temperature, flow rate, and product separation, resulting in a better quality product. However, it’s not recommended for fish fillets as they can become waterlogged and lose flavour. Quick thawing of large quantities of the product and t he thawing system doesn’t take up large amounts of space in the factory.

Air Thawing : not commonly used for large quantities in the seafood industry, but it’s suitable for small amounts of products like fish fillets or individually frozen shellfish. However, this method requires careful attention to thawing times, air temperatures, and hygiene to maintain product quality. The downside is that the operator has limited control over the process. Can be used for products that cannot be water thawed such as fillets or shellfish, minimal loss of flavour.

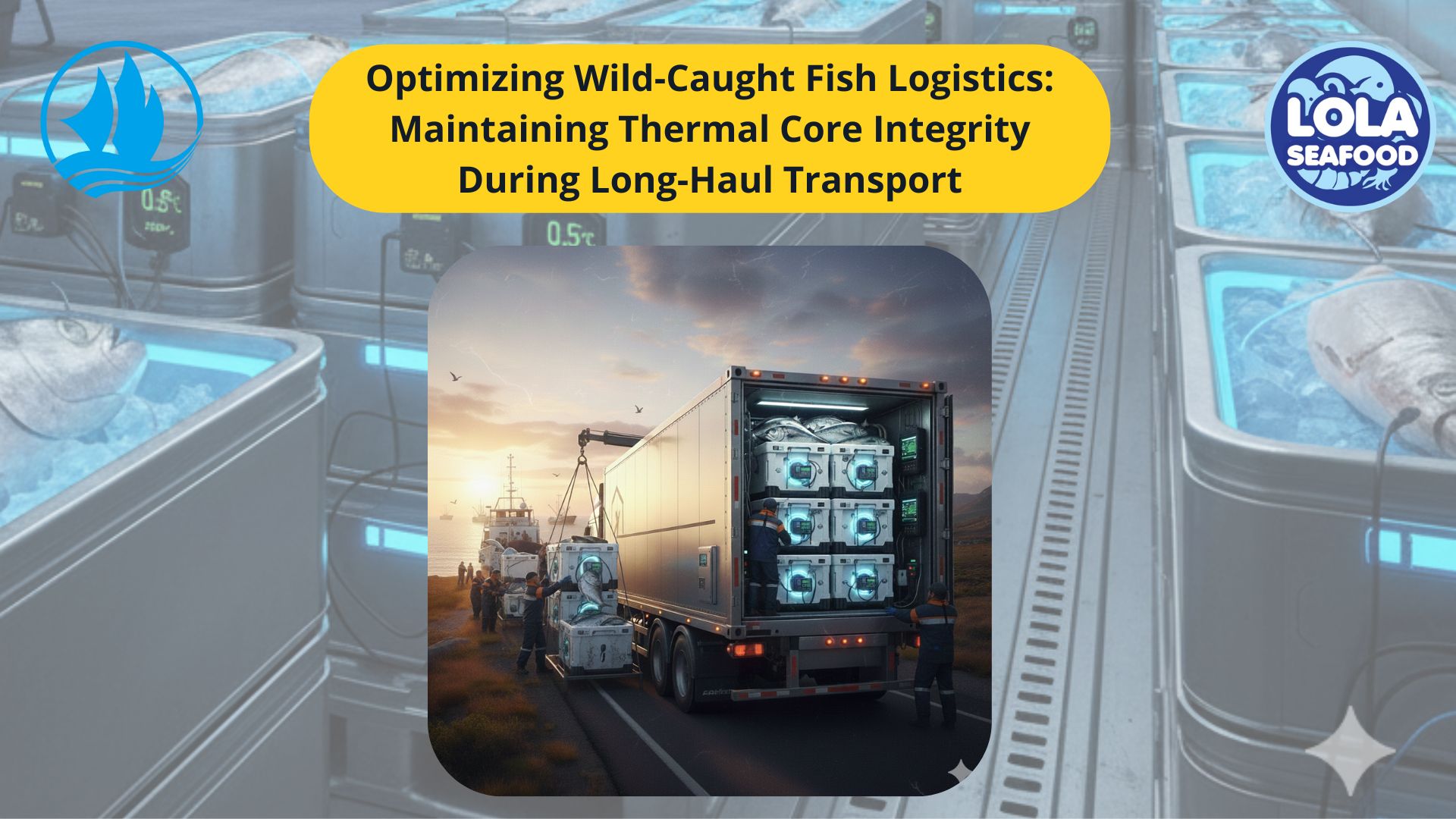

Optimizing Wild-Caught Fish Logistics: Maintaining Thermal Core Integrity During Long-Haul Transport

.jpg)

The Impact of HACCP-Based Integrated Quality Management Programs on the Quality and Competitiveness of Fresh Demersal Fish Products

and Employee Productivity on the Demersal Fish Processing Floor.jpg)

.jpg)