Here Are The Important Role Of Raw Material, Direct Labor, and Factory Overhead Costs In Business Sustainability

By. Fajar - 20 Dec 2024 (3).png)

kelolalaut.com In the world of manufacturing, understanding and managing production costs is essential. Production costs include various components that affect the cost of goods sold and the company's profitability. The three main components of production costs are raw material costs, direct labor costs, and factory overhead costs. This article will discuss these components in detail.

1. Raw Material Costs

Raw material costs refer to the expenses incurred in purchasing the primary materials that will be processed into finished products. These costs include:

- Primary Raw Materials: Materials that form the main part of the finished product, such as fish in the fish processing industry or wood in furniture manufacturing.

- Auxiliary Raw Materials: Supporting materials used in small amounts or with insignificant direct impact on the finished product, such as plastic, master cartons, and others.

Factors Affecting Raw Material Costs

- Market Prices: Fluctuations in raw material prices in the market.

- Purchase Volume: Discounts or wholesale prices often apply to bulk purchases.

- Material Quality: Higher-quality materials usually come at a higher price.

Ways to Control Raw Material Costs

- Use ordering methods like Just-in-Time (JIT) to avoid excess inventory.

- Seek alternative suppliers to obtain the best prices.

2. Direct Labor Costs

Direct labor costs refer to wages paid to employees directly involved in the production process, such as machine operators or assembly line workers.

Components of Direct Labor Costs

- Basic Salaries: The standard wages given to employees.

- Benefits and Incentives: Bonuses, health benefits, or overtime incentives.

Factors Affecting Direct Labor Costs

- Worker Skills: Employees with higher skills typically command higher wages.

- Labor Market Conditions: Competition for skilled workers can influence wages.

Ways to Manage Direct Labor Costs

- Improve work efficiency through training.

- Automate processes where possible to reduce reliance on manual labor.

3. Factory Overhead Costs

Factory overhead costs include all production costs that cannot be directly attributed to raw materials or direct labor. Examples include:

- Electricity and Utilities: Power used to run machines.

- Depreciation Costs: Depreciation of production equipment and machinery.

- Maintenance Costs: Routine maintenance of facilities and machines.

- Support Staff Salaries: Wages for staff not directly involved in production, such as supervisors or janitorial staff.

Factors Affecting Factory Overhead Costs

- Production Volume: Overhead costs are often allocated based on the number of units produced.

- Machine Efficiency: Less efficient machines can increase overhead costs.

Ways to Manage Overhead Costs

- Perform regular maintenance to prevent machine breakdowns.

- Use cost-efficient alternative energy sources.

In Conclusion, raw material costs, direct labor costs, and factory overhead costs are the three main pillars of production cost calculations. Effectively managing these components helps companies improve efficiency, reduce expenses, and increase profitability. By understanding each type of cost, companies can make more strategic decisions in operations and production.

If you are interested in our Bonito Whole Round Bonito Fillet Loin Bonito Fillet Portion Cut please do not hesitate to contact us through email and/or whatsapp

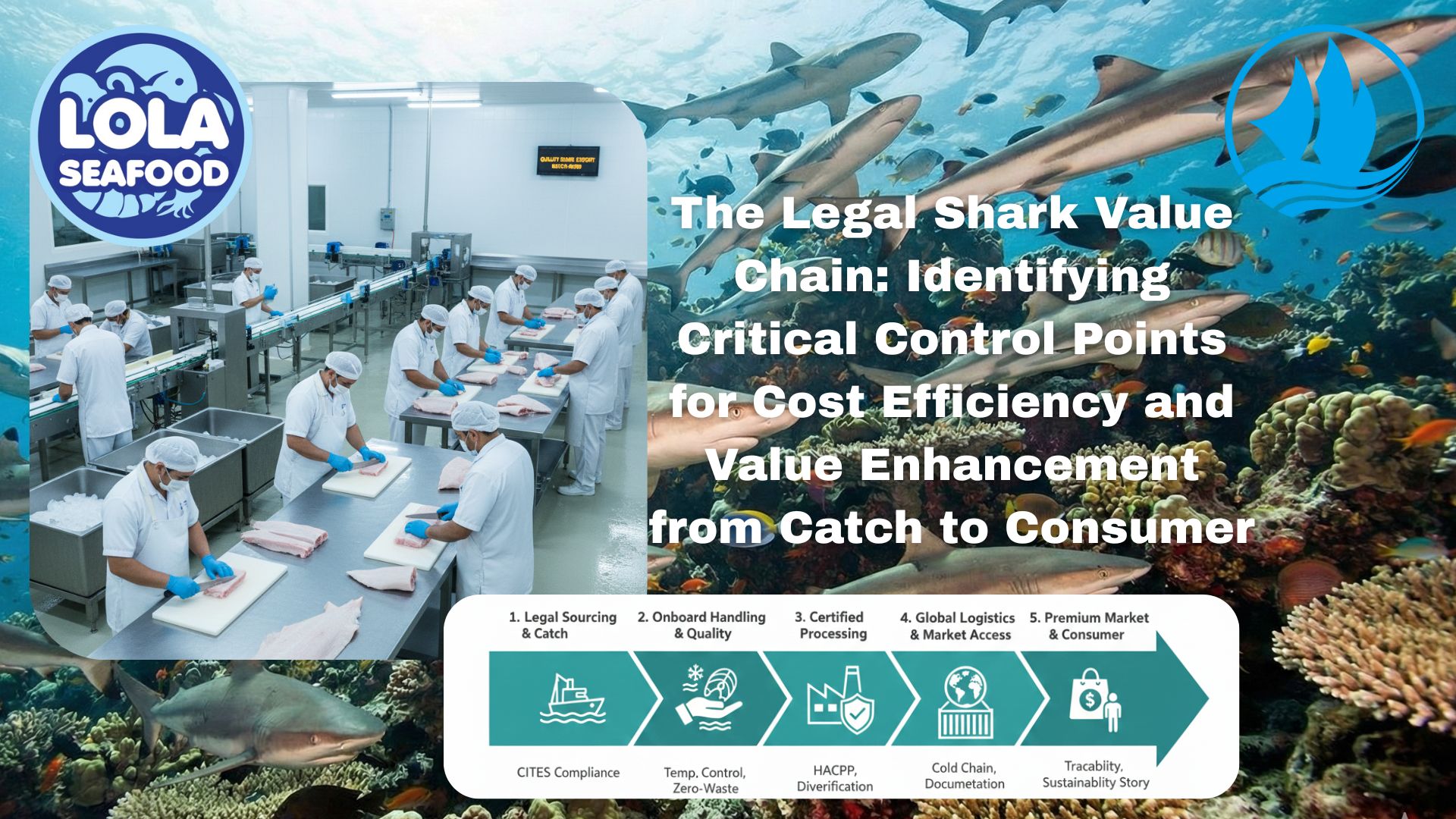

The Legal Shark Value Chain: Identifying Critical Control Points for Cost Efficiency and Value Enhancement from Catch to Consumer

Global Trust Across Three Segments: How the HACCP System Ensures Premium Quality for Demersal, Pelagic Fish, and Legal Shark Product Utilization

.jpg)

Green Investment, Profitable Harvest: How Sustainability Practices Reduce Operating Costs in Fish Fillet Processing Plants (Skin-On and Skin-Less)

in Meeting Global Protein Demand Sustainably.jpg)

Sustainable Aquaculture: The Role of Recirculating Aquaculture Systems (RAS) in Meeting Global Protein Demand Sustainably