X-ray Metal Detection for Frozen Snapper Whole Round Products

By. Sofie Thoriq - 02 Jan 2025.jpg)

Kelolalaut.com In the food industry, ensuring product safety and quality is a critical responsibility. One of the technologies that has revolutionized this process is X-ray inspection, particularly when used for metal detection in frozen products like whole-round snapper. X-ray inspection provides a reliable, non-invasive method to detect foreign contaminants, such as metal, glass, or stones, which can compromise product safety and integrity. For frozen fish products like whole-round snapper, this technology is increasingly important in safeguarding consumer health, ensuring compliance with food safety regulations, and protecting brand reputation.

The Importance of Metal Detection in Frozen Snapper

Frozen snapper, often processed as a whole round product, is a popular choice in many markets due to its nutritional benefits and culinary versatility. However, like many other seafood products, snapper is vulnerable to contamination during the processing and packaging stages. Metal contaminants, which may come from machinery, packaging, or handling equipment, pose a significant risk to consumers. Sharp metal shards can cause severe injury if ingested, and the presence of foreign objects can lead to product recalls, financial loss, and damage to a company’s reputation.

Traditionally, metal detection was done using traditional metal detectors that operate through electromagnetic fields to detect ferrous, non-ferrous, and stainless-steel contaminants. However, these systems have limitations when it comes to detecting metals in frozen or dense products like whole round snapper. The freezing process can affect the sensitivity of metal detectors, making them less effective for high-density products. This is where X-ray inspection technology comes into play.

How X-ray Metal Detection Works

X-ray inspection systems use a highly focused X-ray beam that scans the entire product as it passes through a conveyor belt. The X-ray beam interacts with the product, and a detector measures the radiation that passes through it. Dense materials, such as metals, absorb more X-rays, creating a distinct image pattern that allows the system to detect foreign objects.

In the case of frozen snapper, X-ray inspection is highly effective because it can penetrate the frozen flesh without being hindered by the ice or freezing process. The system can differentiate between the fish’s natural density and any foreign material, even if the contaminant is small or embedded deep within the product. This makes it an ideal solution for frozen food processing, where traditional metal detectors may struggle.

X-ray systems also provide additional benefits over traditional metal detection. They are capable of identifying contaminants not only made of metal but also of other materials like glass, stones, or bone fragments, which may also be found in whole-round fish. This broader detection range ensures higher product safety, reducing the likelihood of harmful contaminants reaching consumers.

Benefits of X-ray Inspection for Frozen Snapper

- Comprehensive Detection: X-ray machines can identify a wide range of foreign objects, including metals, glass, bones, and plastics. This capability is especially important for seafood like snapper, which may contain naturally occurring bones that can be easily confused with contaminants.

- Non-Destructive Testing: Unlike traditional methods such as manual inspection or destructive testing, X-ray inspection is non-invasive. The snapper remains intact, ensuring that the product’s quality and appearance are not compromised during the detection process.

- Increased Sensitivity: X-ray inspection offers superior sensitivity, especially in frozen products. It is not affected by the freezing process, unlike metal detectors that may struggle with detecting metals in dense or frozen products. This allows for more accurate and efficient detection.

- Regulatory Compliance: Many countries have stringent food safety regulations that require food producers to ensure their products are free from foreign contaminants. By using X-ray metal detection, producers can meet these regulations and avoid costly recalls, fines, and reputational damage.

- Enhanced Brand Protection: Contaminated products can lead to negative publicity and loss of customer trust. By investing in X-ray inspection technology, companies demonstrate their commitment to quality and safety, which can strengthen consumer confidence and enhance brand loyalty.

- Automation and Efficiency: X-ray systems are automated and can process large volumes of frozen snapper efficiently. This reduces labour costs and human error, improving overall production efficiency while maintaining high safety standards.

Challenges and Considerations

Despite the advantages, there are some challenges to using X-ray inspection for frozen snapper. The primary concern is the high initial investment in X-ray equipment. However, considering the long-term benefits, such as reduced product recalls, compliance with regulations, and enhanced brand reputation, the return on investment can be significant.

Another consideration is the need for routine maintenance and calibration of X-ray machines to ensure consistent performance. Additionally, while X-ray systems are highly effective, they are not foolproof and should be used in conjunction with other quality control measures to maintain the highest standards of product safety.

X-ray metal detection is a powerful tool in the food industry, particularly for frozen snapper whole-round products. It offers a non-destructive, sensitive, and efficient method to detect metal and other foreign contaminants that may pose a risk to consumers. By investing in X-ray inspection technology, seafood producers can enhance product safety, comply with regulatory requirements, and protect their brand. As consumer expectations for food safety continue to rise, X-ray inspection will undoubtedly play a crucial role in ensuring that the seafood industry remains competitive and trustworthy.

if you are interested in our Goldband / Crimson Snapper Whole Round, Goldband / Crimson Snapper Fillet Skin On, White Snapper / Robinson Seabream / Seabream Whole Round / Whole Gilled Gutted Scaled, White Snapper / Robinson Seabream / Seabream Fillet Skin On, Snapper Whole Round / Whole Gilled Gutted Scaled, Red / Scarlet Snapper Fillet Portion, Red / Scarlet Snapper Fillet Skin On, Snapper Fillet Skinless please do not hesitate to contact us to email and / or whatsap

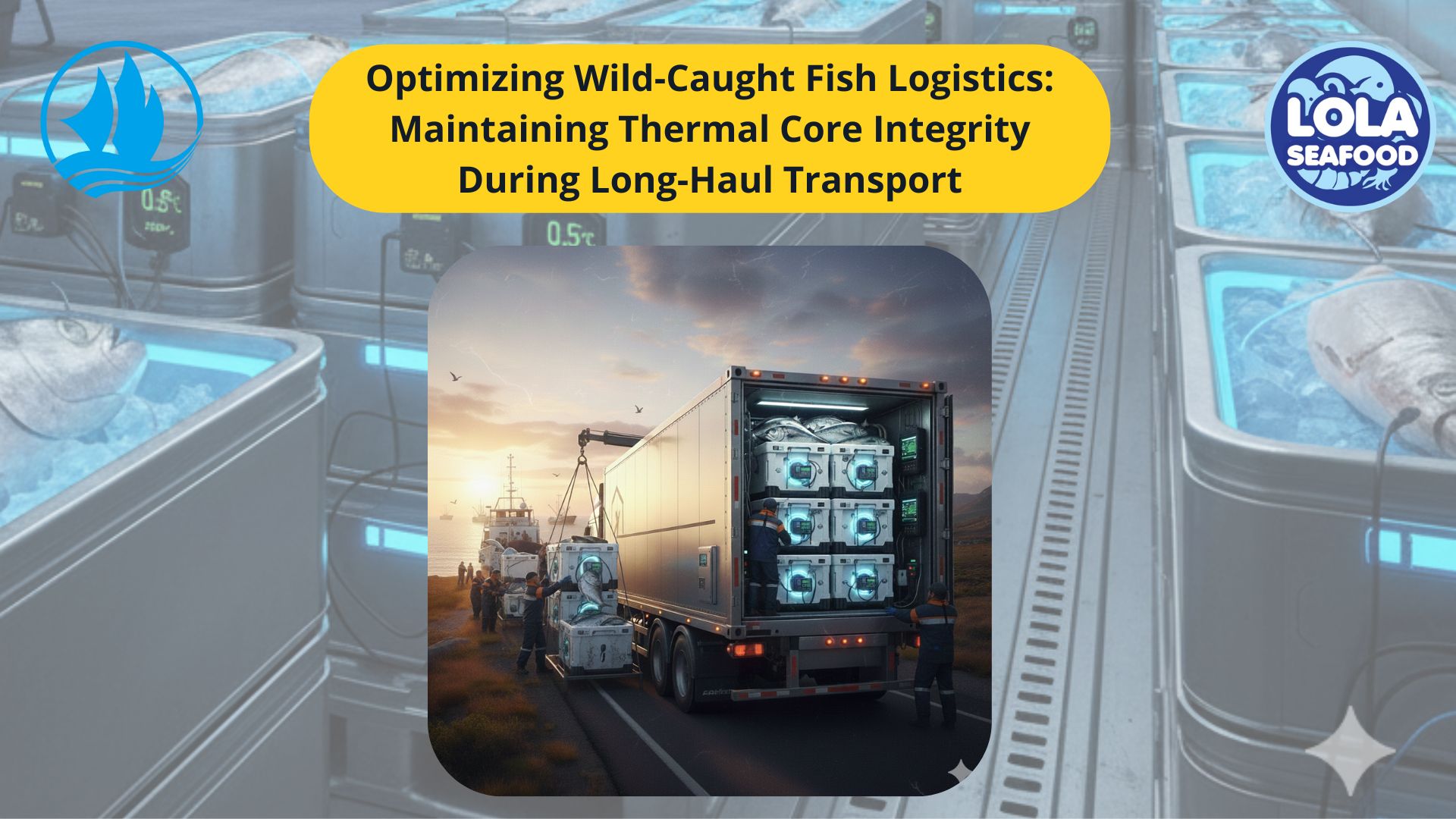

Optimizing Wild-Caught Fish Logistics: Maintaining Thermal Core Integrity During Long-Haul Transport

.jpg)

.jpg)

and Employee Productivity on the Demersal Fish Processing Floor.jpg)