The Importance of Monitoring Final Output Quality and Strategic Employee Allocation in Fish Processing Plants to Enhance Company Profitability

By. Fajar - 25 Nov 2025

kelolalaut.com In the highly regulated and competitive seafood industry, fish processing companies are required to demonstrate operational excellence, strict adherence to quality standards, and efficient resource utilization. To meet these expectations, two key operational components play a central role: precise monitoring of final output quality and strategic allocation of employees across the production line. When managed effectively, these elements support product integrity, streamline workflow efficiency, and directly contribute to the company’s financial performance.

1. Final Output Quality as a Corporate Priority

Final output quality represents the culmination of all processing activities and therefore must reflect the company’s commitment to safety, reliability, and customer satisfaction. Export-oriented fish processors must comply with international regulations such as EU standards, FDA rules, and requirements from major importing countries. Failure to meet these standards can result in shipment rejections, financial penalties, or loss of market access.

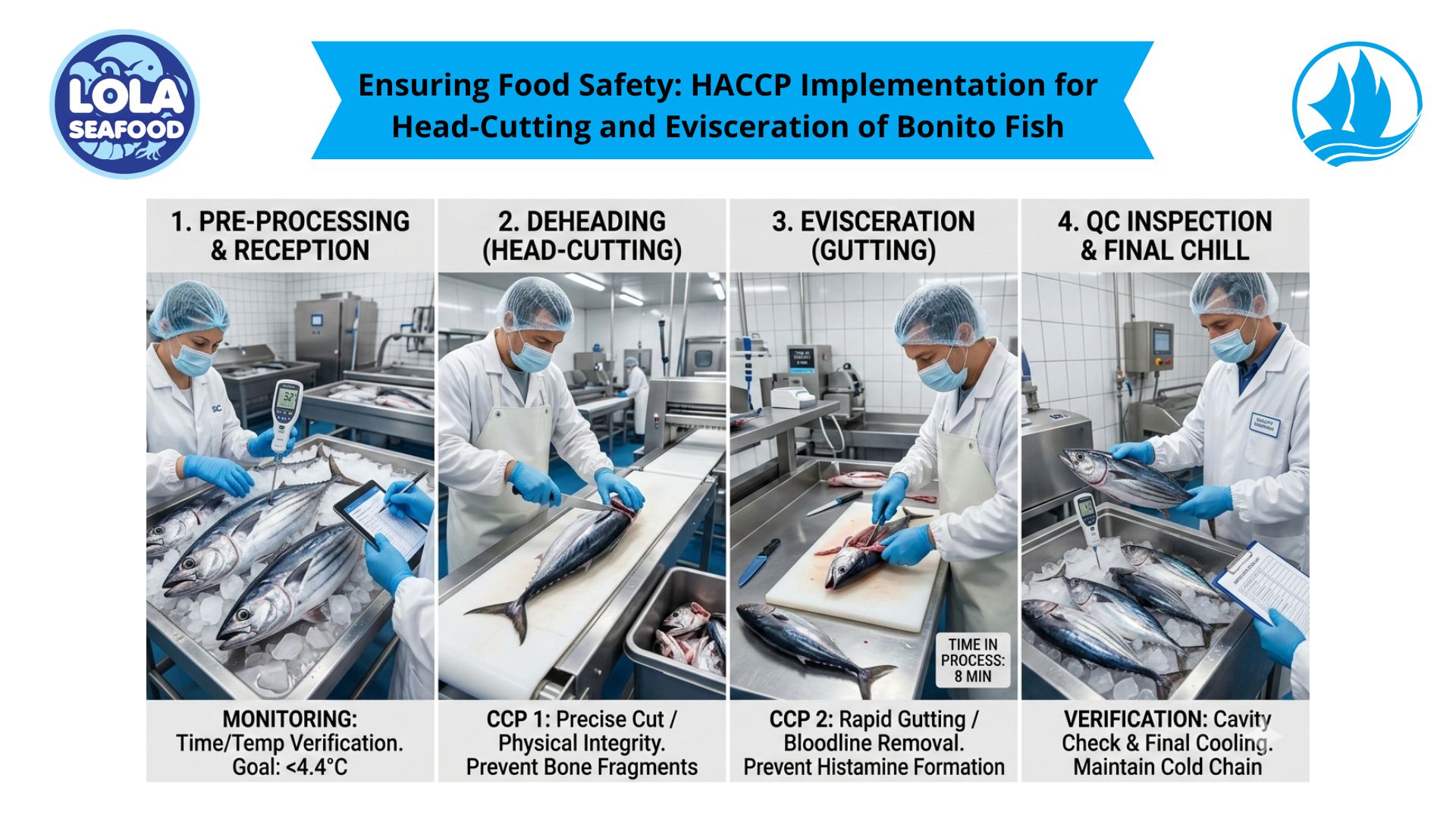

Thorough inspections at the final stage involve evaluating physical appearance, freshness, trimming precision, temperature stability, and packaging quality. This comprehensive assessment ensures that only products meeting company specifications and buyer requirements are approved for distribution.

Strict monitoring also reduces the likelihood of wastage, as early detection of defects helps prevent large-scale errors from progressing further into the supply chain. In addition, data gathered from final inspection results provide valuable insights for continuous improvement, allowing management to identify root causes of recurring issues and implement corrective actions.

2. Strategic Employee Allocation for Operational Efficiency

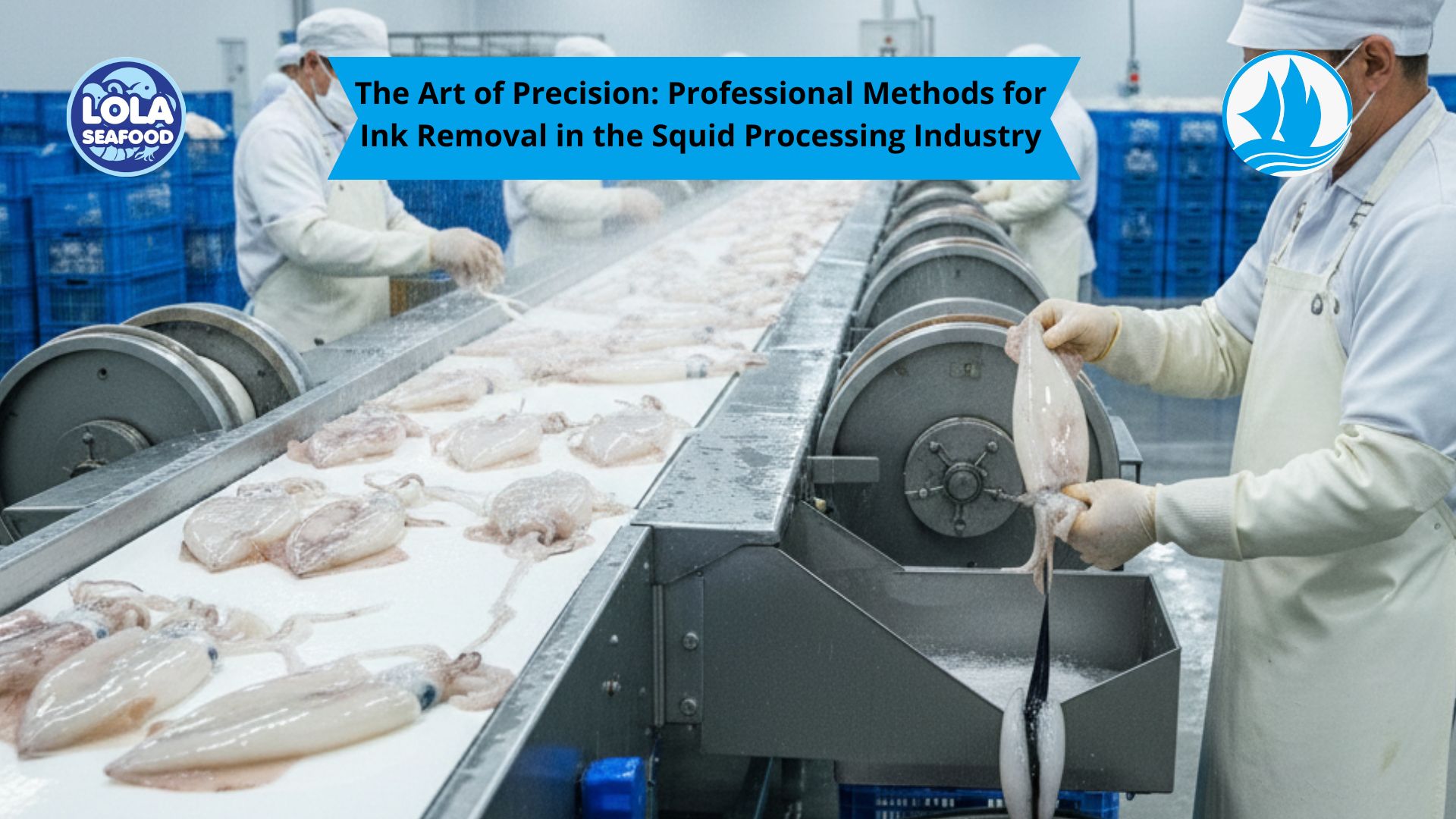

Strategic workforce distribution is essential to maintaining a smooth and efficient production environment. Each processing phase—receiving, washing, grading, filleting, trimming, packing, freezing, and storage—requires an adequate number of employees with appropriate skills. Balanced staffing helps prevent bottlenecks, ensures consistent workflow, and maintains production targets.

Skill-based placement further enhances operational performance. Experienced filleting staff can increase yield percentages from raw materials, while detail-oriented workers in packing and inspection roles help secure compliance with export specifications. These strategic assignments not only elevate product quality but also improve resource utilization.

Improper employee allocation, on the other hand, results in uneven workloads, idle time in some departments, and excessive strain in others. Such imbalances can slow down production, decrease overall efficiency, and increase labor costs. Effective allocation supports optimal process flow and contributes to improved productivity across all operational stages.

3. Workforce Development and Production Flexibility

Beyond allocation, continuous workforce development is essential for long-term operational reliability. Regular training programs ensure employees remain knowledgeable about hygiene standards, handling procedures, and equipment usage. This minimizes processing errors and reinforces the company’s compliance with international safety standards.

Cross-training employees increases operational flexibility, enabling them to support multiple departments when required. During peak seasons or unforeseen staff shortages, multi-skilled workers help maintain production continuity without compromising product quality or delivery schedules.

Investing in employee development also supports organizational stability. A well-trained and confident workforce tends to demonstrate higher productivity, stronger engagement, and greater commitment to company goals.

4. Strengthening Competitive Advantage and Business Performance

The combined impact of strong final output monitoring and effective employee allocation provides a solid foundation for enhanced profitability and competitive positioning. High-quality products with consistent standards foster buyer trust, strengthen long-term business relationships, and position the company as a reliable partner in global seafood markets.

Operational efficiency achieved through strategic labor allocation reduces production delays, improves yield ratios, and supports optimal resource usage. These improvements lead to lower operational costs and higher profit margins.

Moreover, a company that continuously demonstrates product consistency, regulatory compliance, and workforce efficiency gains a competitive advantage, enabling it to secure premium market segments and expand its international presence.

5. Organizational Commitment Toward Operational Excellence

As market demands continue to evolve and quality expectations rise, fish processing companies must maintain a strong organizational commitment to operational excellence. This commitment involves aligning management strategies, production processes, and human resource systems to ensure consistent delivery of high-quality products.

Strengthening internal coordination, enhancing communication between departments, and regularly evaluating performance indicators are essential steps in sustaining continuous improvement. By embedding quality and efficiency into daily operations, companies position themselves not only to meet current industry standards but also to anticipate future regulatory and market challenges.

If youre interested in our Barramundi Whole Round / Whole Gilled Gutted Scaled , Barramundi Fillet Skinless , Barramundi Fillet Skin On and Barramundi Fillet Portion Cut, snapper please do not hesitate to contact us through email and/or Whatsapp