The Influence of Employee Performance on Enhancing Production Output in the Frozen Fish Processing and Packaging Industry

By. Ely Kusniawati - 26 Nov 2025

kelolalaut.com The frozen fish processing and packaging industry plays a vital role in supplying global markets with safe, high-quality seafood products. As consumer demand and export requirements continue to rise, companies within this sector must consistently achieve efficient production performance while maintaining strict quality and safety standards. In this highly competitive environment, the contribution of employee performance becomes one of the most decisive factors influencing overall operational success. Every stage of the production chain—from handling raw materials to processing, freezing, and packaging—relies heavily on the skills, discipline, and coordination of the workforce. When employees demonstrate competence and strong work ethics, production workflows run smoothly, waste is minimized, and product quality is preserved. Therefore, understanding the significance of employee performance is essential for companies aiming to enhance production output, strengthen operational stability, and remain competitive in the international frozen seafood market.

1. Importance of Employee Performance in Production Operations

Employee performance plays an essential role in determining the efficiency and productivity of frozen fish processing and packaging operations. As global seafood demand continues to grow, companies must ensure that their workforce is capable of meeting production targets while maintaining strict quality and safety standards. Employees who demonstrate strong technical abilities, discipline, and attention to detail contribute directly to reduced downtime, fewer processing errors, and smoother workflow execution. In an industry where precision and timing are crucial, the overall performance of employees becomes a decisive factor in achieving consistent production output.

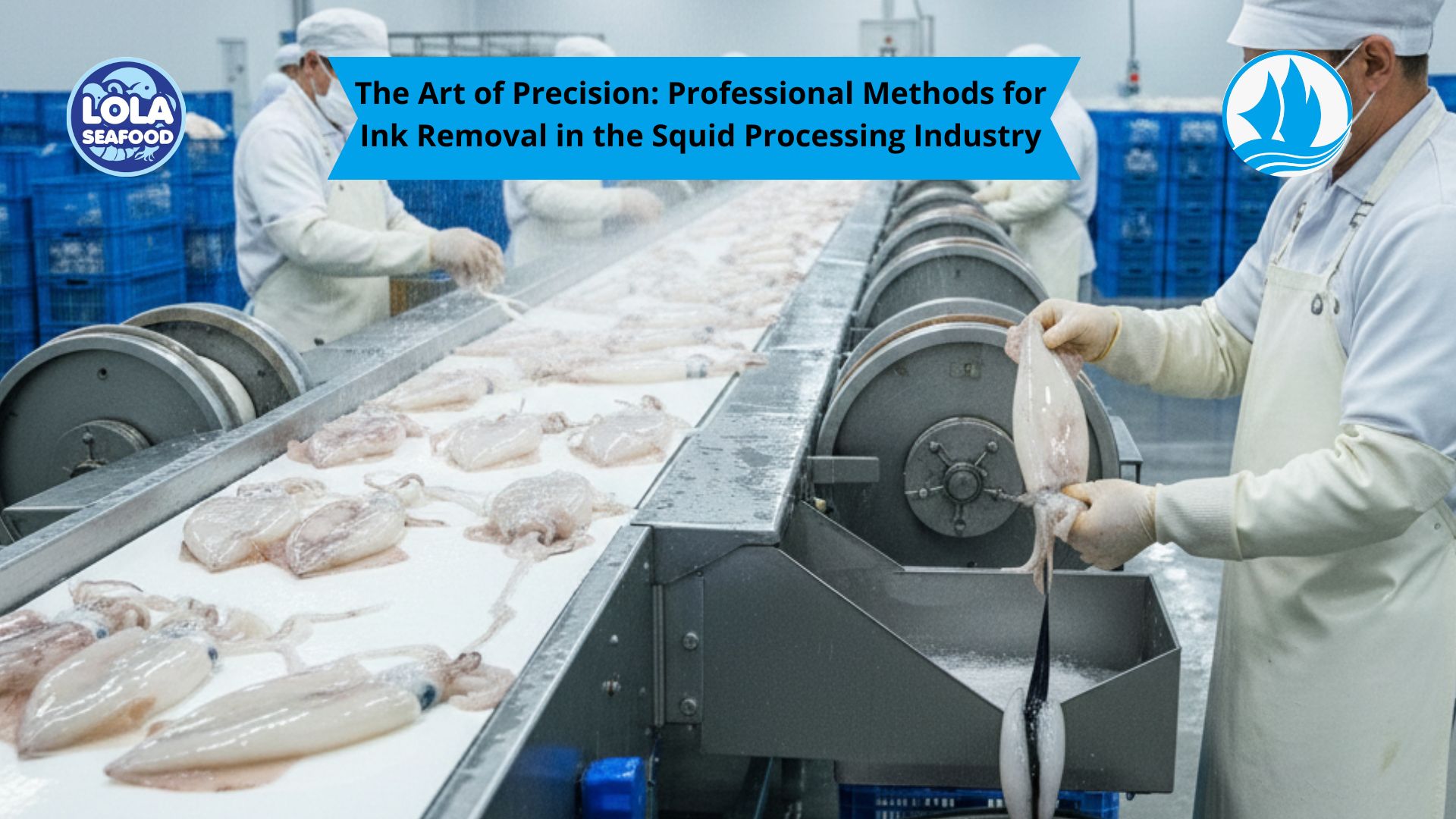

2. Impact on Raw Material Handling and Processing Accuracy

The initial stages of frozen fish processing—receiving, sorting, grading, cleaning, and filleting—depend heavily on employee skill and accuracy. Workers must be able to identify fish species, determine quality grades, and handle materials according to established procedures. When employees perform these tasks effectively, companies can minimize waste, avoid product damage, and ensure that fish are processed within optimal time windows to preserve freshness. High performance in this phase also supports better yield management, as experienced employees can maximize the usable portion of each fish, contributing to improved production volume.

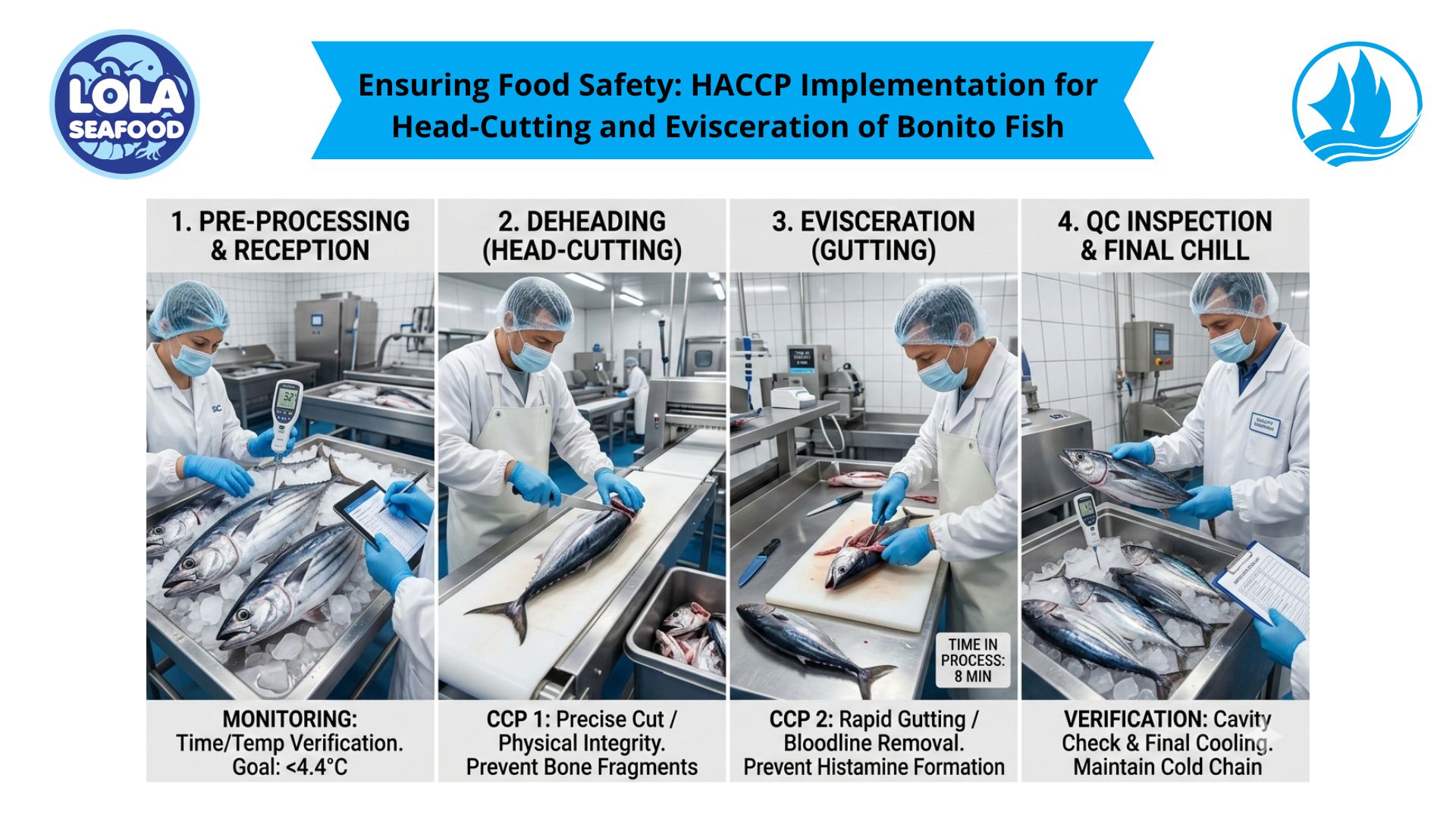

3. Role in Maintaining Hygiene and Food Safety Standards

Compliance with food safety standards such as HACCP and Good Manufacturing Practices (GMP) requires consistent employee discipline. Production staff must follow sanitation procedures, use protective gear, and maintain cleanliness throughout the processing environment. Strong employee performance in hygiene practices reduces contamination risks and ensures that products meet international market requirements. Even a small lapse in individual performance can disrupt production, cause non-compliance incidents, or necessitate reprocessing. Therefore, employee adherence to hygiene protocols significantly affects both production continuity and product reliability.

4. Contribution to Line Efficiency and Workflow Coordination

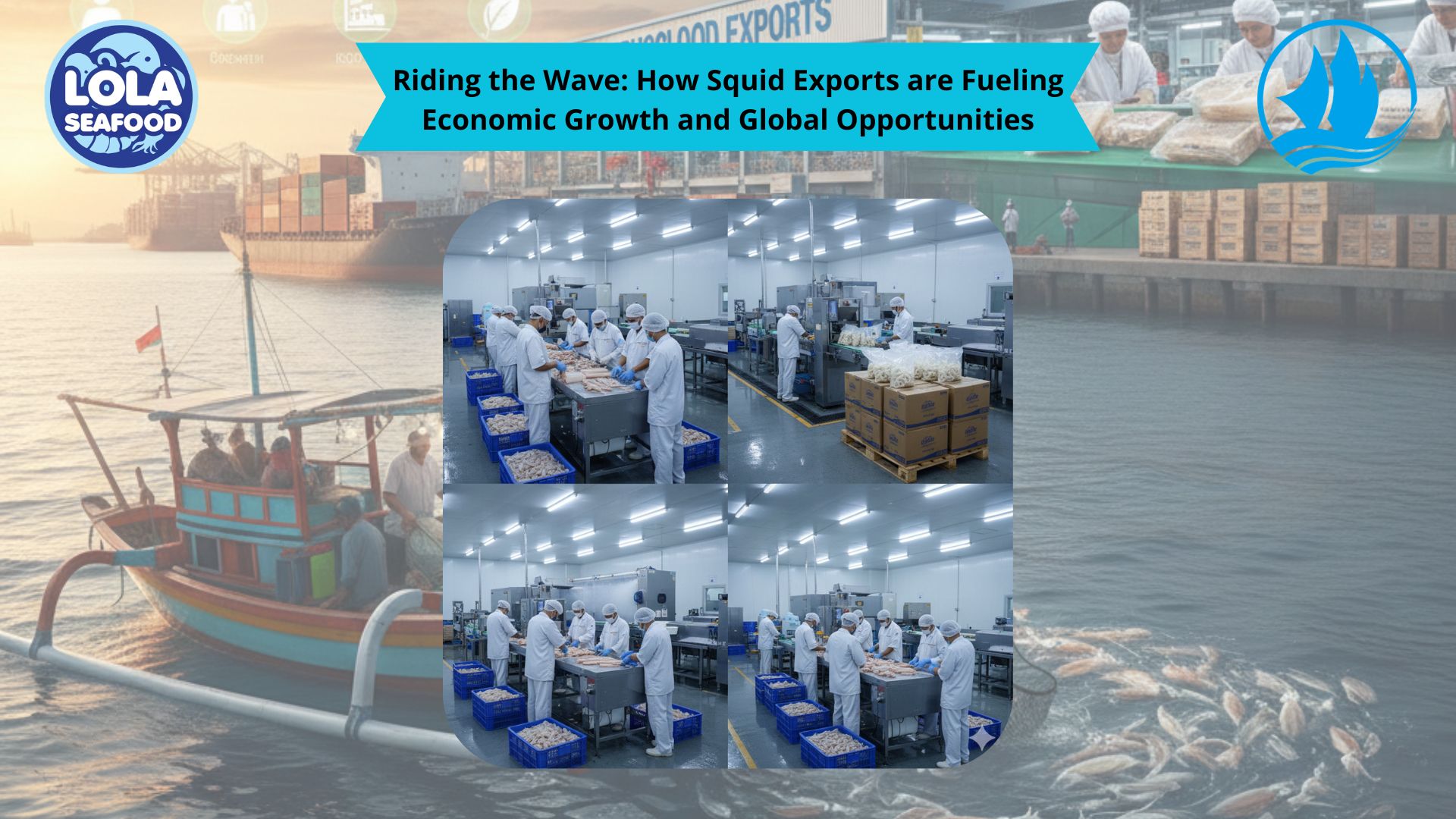

The frozen fish industry relies on interconnected processing lines where each stage must operate in harmony with the next. Employee performance directly determines the speed and efficiency of these workflows. Workers who understand their roles, maintain consistent output levels, and collaborate effectively help prevent bottlenecks that could slow down production. Efficient employees also respond quickly to operational challenges, equipment issues, or unexpected surge demands, supporting a stable production pace. This synchronized coordination is essential for meeting daily and weekly production targets, particularly during peak export periods.

5. Influence of Training and Skill Development Programs

Employee performance improves significantly when companies invest in ongoing training. Regular instruction on machinery operation, updated hygiene standards, and improved processing techniques equips employees with the knowledge necessary to perform tasks efficiently and safely. Training enhances technical capability, reduces mistakes, and boosts confidence, allowing workers to contribute more effectively to overall production goals. Additionally, well-trained employees adapt more easily to new technologies or process changes, enabling companies to implement operational improvements without major disruptions.

6. Importance of Communication and Team Collaboration

Effective communication among employees is essential for maintaining production consistency. In frozen fish processing and packaging, close coordination between teams—such as raw material handling, processing, freezing, quality control, and packing—is critical. Employees who communicate clearly can resolve issues faster, prevent misunderstandings, and ensure that each department supports the flow of work. Strong teamwork enhances efficiency, stabilizes production cycles, and minimizes delays that may arise from misaligned tasks or incomplete information.

7. Influence of Employee Well-Being on Work Performance

Employee well-being significantly affects productivity levels. Fatigue, discomfort, or high stress can reduce focus and increase the likelihood of errors. In a cold working environment such as frozen fish processing, ergonomic workstations, proper protective clothing, and manageable shift schedules are essential to maintaining employee stamina. Companies that prioritize safety, motivation, and welfare foster a more engaged workforce. Higher morale leads to improved performance, reduced absenteeism, and more consistent production results.

8. Strategic Value of Strong Employee Performance for Industry Competitiveness

In a competitive global seafood market, the ability to meet deadlines, maintain quality, and deliver consistent volumes strongly depends on employee performance. Companies with a high-performing workforce can respond more effectively to market fluctuations, adjust production capacity, and meet international buyer expectations. Beyond operational benefits, strong employee performance also enhances the company’s reputation, strengthens customer trust, and creates opportunities for market expansion.

9. Reinforcement of Company Sustainability Through Workforce Excellence

Strong employee performance supports long-term productivity and operational sustainability. When employees consistently deliver high-quality work, companies experience reduced waste, optimized resource use, and lower operational costs. This efficiency contributes to financial stability and enables reinvestment in technology upgrades, training programs, and improved working conditions. Ultimately, a skilled and dedicated workforce becomes the foundation for sustainable growth in the frozen fish processing and packaging sector.

If you are intrested in our Goldband / Crimson Snapper Whole Round, Goldband / Crimson Snapper Fillet Skin On, White Snapper / Robinson Seabream / Seabream Whole Round / Whole Gilled Gutted Scaled, White Snapper / Robinson Seabream / Seabream Fillet Skin On, Snapper Whole Round / Whole Gilled Gutted Scaled, Red / Scarlet Snapper Fillet Portion, Red / Scarlet Snapper Fillet Skin On, Snapper Fillet Skinless please do not hesitate to contact us to email and / or whatsap