The Critical Importance of Proper Fish Handling to Prevent Histamine Accumulation in Industrial Settings

By. Ely Kusniawati - 04 Dec 2025

kelolalaut.com Histamine, a naturally occurring biogenic amine, is generally associated with allergic reactions. However, in the context of food safety, particularly with fish, its presence can signify a serious public health hazard leading to Scombroid Poisoning, or Histamine Fish Poisoning (HFP). For the industrial-scale fish processing sector, understanding and strictly controlling the factors that lead to histamine formation is not just a matter of compliance, but a fundamental necessity for consumer safety and brand integrity. This article explores the critical importance of good fish handling practices in industrial settings to mitigate the risk of histamine contamination.

What is Histamine and How is it Formed?

Histamine is produced when certain bacteria proliferate in fish tissue and possess the enzyme histidine decarboxylase. This enzyme acts on the naturally high levels of free amino acid histidine found in the muscle of fish, particularly in the Scombridae family (tuna, mackerel, bonito) and other species like mahi-mahi and sardines. The chemical reaction is simple but the consequences are significant: histidine is converted into histamine.

Crucially, temperature abuse is the primary catalyst. When fish are kept above a certain temperature threshold—typically 15∘C (59∘F), but even temperatures above 4∘C (39∘F) can allow the process to begin—the bacteria multiply rapidly, and the histamine levels can reach toxic concentrations in just a few hours. Unlike many other bacterial food safety hazards, histamine is heat-stable, meaning that cooking, smoking, canning, or freezing will not destroy the toxin once it has formed. This emphasizes that prevention is the only effective control measure.

The Industrial Challenge: Scale and Speed

In an industrial setting, the volume of fish processed is immense, which exponentially increases the risk if control points are missed. The sheer scale requires robust, verifiable, and continuously monitored controls across the entire supply chain, often referred to as a "cold chain."

1. Immediate Post-Catch Chilling

The journey to prevent histamine begins the moment the fish is caught. For industrial fishing vessels, the goal must be to rapidly and thoroughly chill the catch. Systems like Refrigerated Sea Water (RSW) or Iced Sea Water (ISW) are preferred for large volumes, ensuring the core temperature of the fish is brought down to as close to 0∘C (32∘F) as possible, ideally within the first two hours. This step is the most critical: a 1∘C difference can significantly alter the bacterial growth rate.

2. Processing Plant Controls

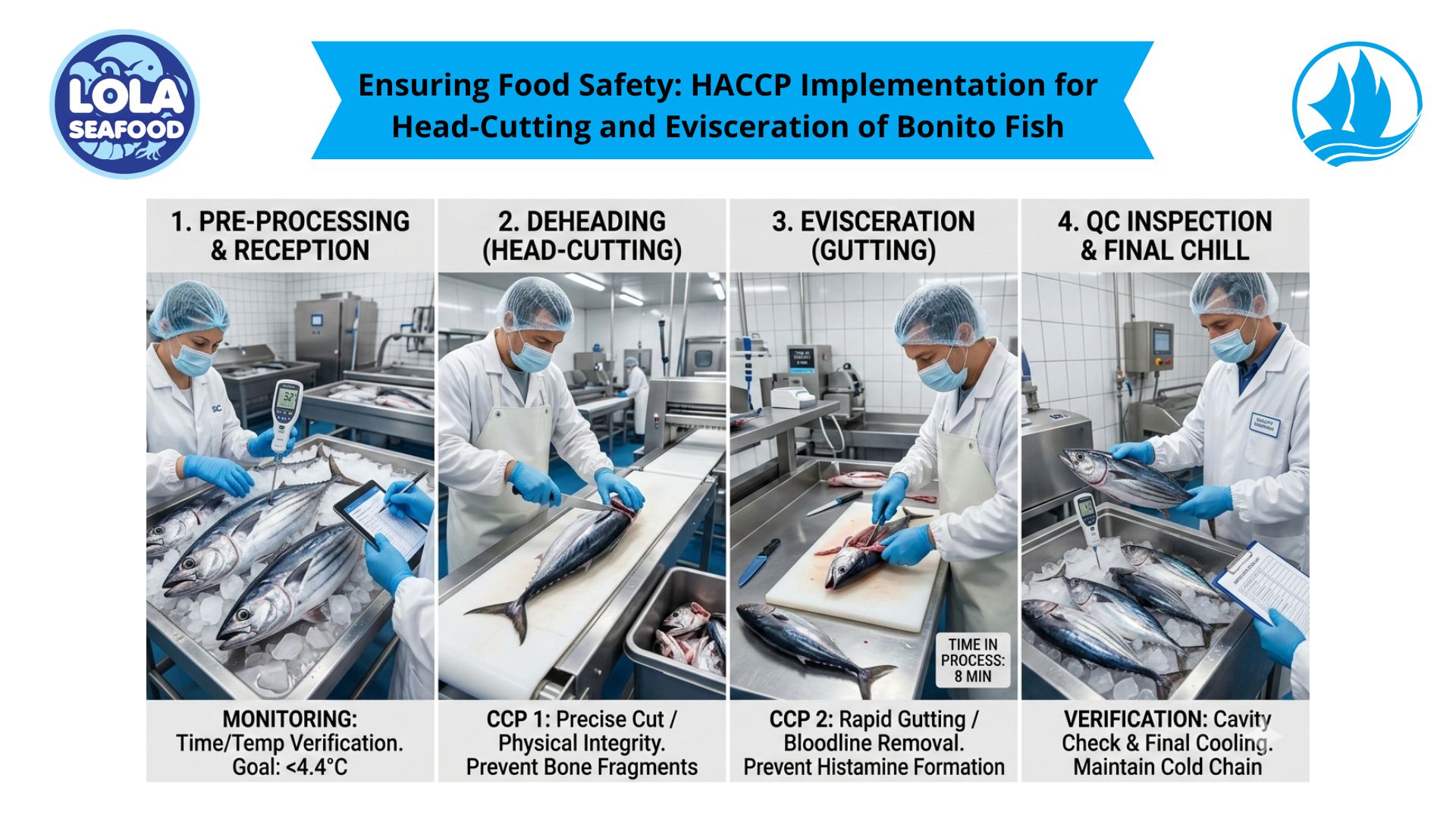

Upon arrival at the processing plant, strict HACCP (Hazard Analysis and Critical Control Point) protocols must be in place, with histamine formation being a recognized hazard.

- Receiving: The temperature of the incoming raw material must be checked and documented. Any lots that show evidence of temperature abuse (e.g., core temperature above 4∘C) should be immediately segregated and rejected, as the histamine may already be present.

- Processing Line: Throughout filleting, cutting, and other preparation steps, the fish should be handled in a temperature-controlled environment (e.g., a chilled room). Minimizing the time the fish spends outside of chilling is essential. Processing equipment must also be kept impeccably clean and sanitized to reduce the bacterial load that could initiate the conversion.

- Storage and Distribution: Finished products, whether fresh or frozen, must maintain the continuous cold chain. Freezing below−18∘C is vital for long-term storage, although it only stops the formation of histamine; it does not eliminate any that formed pre-freezing.

The Consequences of Failure

Failure to implement effective histamine control measures carries severe consequences, both for public health and the business itself.

- Public Health: Scombroid poisoning symptoms, including flushing, headache, palpitations, dizziness, and sometimes respiratory distress, usually appear quickly after consumption. While rarely fatal, they are highly unpleasant and necessitate medical attention.

- Regulatory Action: Industrial histamine contamination often leads to large-scale product recalls, which are financially devastating and cause significant supply chain disruption. Regulatory bodies like the FDA or European Union have strict legal limits for histamine content (e.g., generally below 50 mg/kg in most countries for non-fermented fish), and exceeding these limits triggers enforcement action.

- Reputational Damage: A highly publicized product recall due to food poisoning can irreparably damage a company's brand, leading to a permanent loss of consumer trust and market share.

Continuous Monitoring and Training

The solution is not a one-time fix but a commitment to a culture of food safety. This includes:

- Regular Testing: Implementing a testing regime for incoming raw material and finished products using validated analytical methods (e.g., HPLC or enzymatic assays) to verify the effectiveness of the control plan.

- Equipment Calibration: Ensuring that all thermometers, sensors, and chilling units are regularly calibrated to provide accurate temperature data.

- Staff Training: All personnel, from the fishing crew to the processing line workers and quality assurance team, must be thoroughly trained on the critical role of time and temperature control in preventing histamine formation.

In conclusion, for industrial fish processors, the control of histamine is a Critical Control Point (CCP) that underpins the entire food safety operation. By focusing on rapid, continuous, and verifiable chilling from the point of catch to the final distribution, companies can effectively eliminate this invisible hazard, protect consumers, and maintain the integrity of their products. Good handling is safe handling.

These applications highlight the potential of fish scales beyond traditional uses, driven by advancements in material science.

If youre interested in our Barramundi Whole Round / Whole Gilled Gutted Scaled , Barramundi Fillet Skinless , Barramundi Fillet Skin On and Barramundi Fillet Portion Cut, snapper please do not hesitate to contact us through email and/or Whatsapp