The Role and Importance of Anterooms in the Frozen Fish Industry

By. Najih - 02 Jul 2024.jpg)

In the frozen fish industry, maintaining strict hygiene standards is crucial to ensure product safety and quality. Anterooms play a vital role in this process by serving as a buffer zone between external environments and critical production areas. This article explores the significance of anterooms, their design considerations, and their impact on hygiene and operational efficiency in frozen fish processing facilities.

1. Understanding Anterooms in Frozen Fish Facilities

Anterooms, also known as buffer zones or airlocks, are transitional spaces designed to control the flow of personnel, materials, and equipment into sanitized production areas. These rooms help minimize the introduction of contaminants such as dust, microbes, and airborne pathogens that could compromise the hygiene of the production environment.

2. Design and Construction Features

Effective anteroom design focuses on creating a barrier that reduces the transmission of contaminants. Key features include:

- Air pressure differentials to prevent outside air from entering the production area.

- Dedicated hand washing and sanitization stations for personnel entering and exiting.

- Flooring and wall materials that are easy to clean and disinfect.

- Controlled access points with automated doors or air curtains to maintain air quality.

3. Hygiene Protocols and Best Practices

Anterooms serve as checkpoints where personnel undergo hygiene protocols before entering sanitized areas. These protocols typically include:

- Changing into sanitized work attire, including footwear and protective gear.

- Hand washing and disinfection procedures to minimize the risk of microbial transfer.

- Inspection of personal belongings and tools to ensure they meet cleanliness standards.

4. Impact on Product Quality and Safety

Maintaining strict control over hygiene in anterooms directly contributes to the overall quality and safety of frozen fish products. By preventing contamination at the entry point, anterooms help:

- Reduce the risk of microbial growth and spoilage during processing and storage.

- Ensure compliance with food safety regulations and industry standards.

- Enhance consumer confidence in the safety and reliability of frozen fish products.

5. Future Trends and Innovations

As technology advances, anterooms are evolving to incorporate automated systems for monitoring air quality, temperature, and personnel movements. Future innovations may include:

- Integration with IoT (Internet of Things) devices for real-time monitoring and data analytics.

- Enhanced air filtration and purification systems to further minimize airborne contaminants.

- Adoption of robotics and AI for automated cleaning and disinfection processes.

Human Resource Management Challenges and Training Needs in Implementing HACCP Quality Standards within the Fish Processing Industry

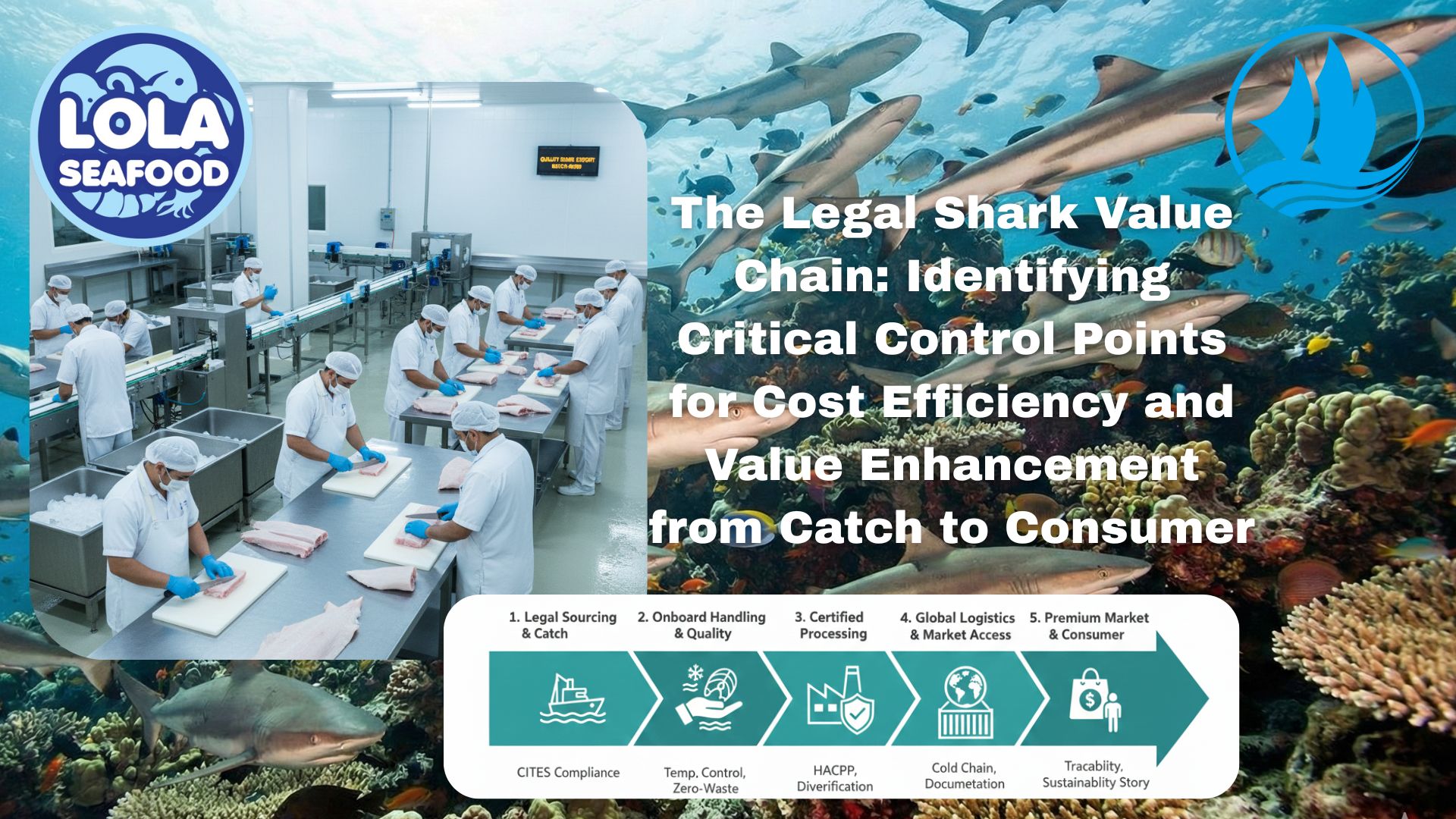

The Legal Shark Value Chain: Identifying Critical Control Points for Cost Efficiency and Value Enhancement from Catch to Consumer

Global Trust Across Three Segments: How the HACCP System Ensures Premium Quality for Demersal, Pelagic Fish, and Legal Shark Product Utilization

.jpg)

in Meeting Global Protein Demand Sustainably.jpg)