The Role of Wall Thermometers in the Frozen Fish Industry

By. Najih - 19 Jul 2024.jpg)

In the frozen fish industry, precise temperature control is critical to maintaining product quality and safety throughout processing, storage, and distribution. Wall thermometers play a crucial role in monitoring and ensuring these optimal conditions. This article explores the significance of wall thermometers in the frozen fish industry, their benefits, and their impact on product integrity.

Importance of Temperature Monitoring

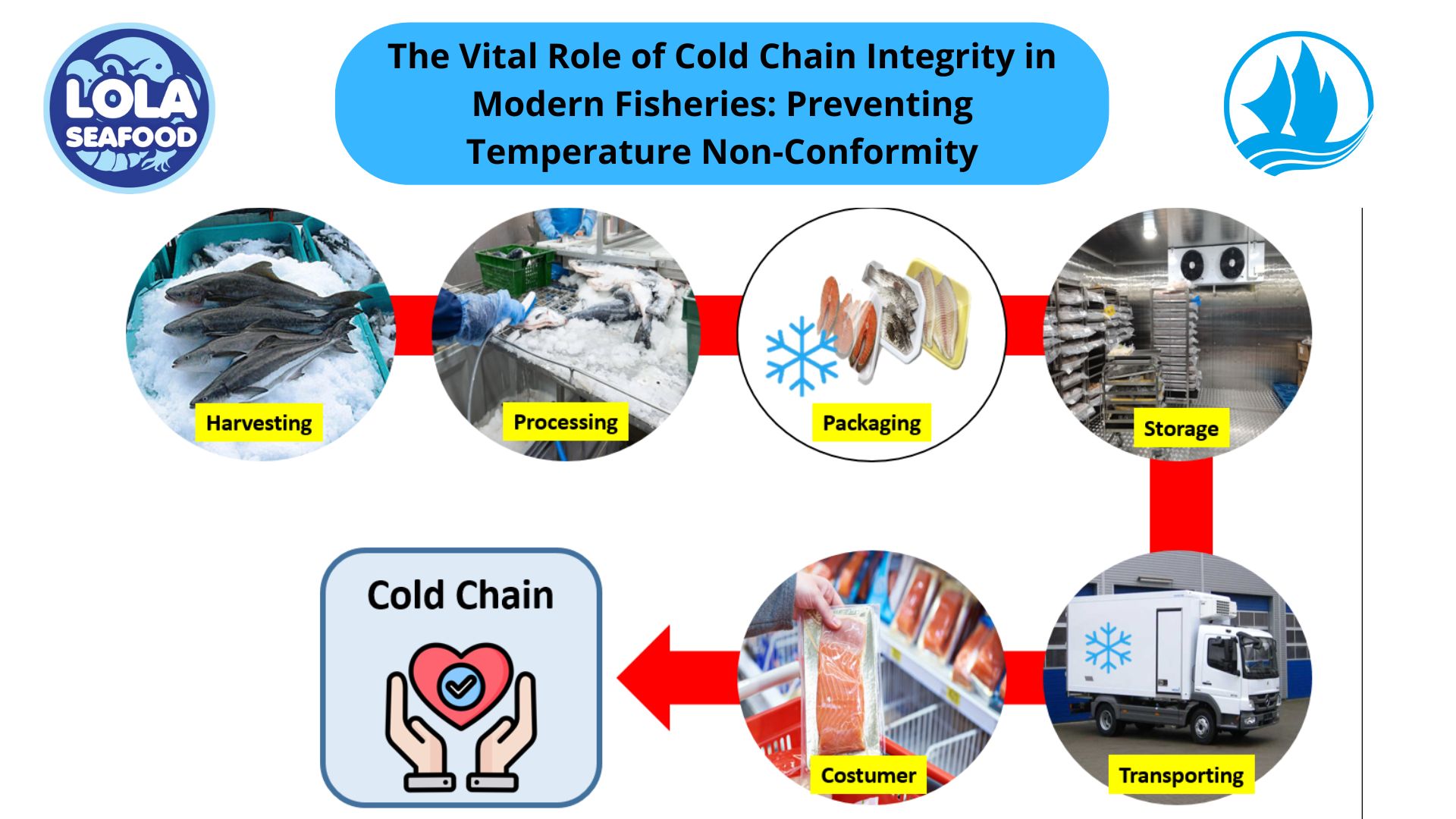

Temperature management is fundamental in preserving the freshness and quality of frozen fish. Fluctuations in temperature can lead to spoilage, bacterial growth, and loss of texture and flavor. Therefore, maintaining consistent and appropriate temperatures at various stages of production and storage is essential.

Role of Wall Thermometers

Wall thermometers are strategically placed in key areas of processing facilities, cold storage rooms, and transportation vehicles involved in the frozen fish supply chain. They provide real-time temperature readings that enable operators to monitor conditions continuously. This proactive approach allows for immediate adjustments to prevent temperature deviations that could compromise product quality.

Benefits of Wall Thermometers

- Accuracy: Wall thermometers provide accurate temperature readings, ensuring compliance with food safety regulations and quality standards.

- Monitoring Efficiency: They facilitate efficient monitoring across large storage areas and processing facilities, allowing for timely interventions if temperature thresholds are exceeded.

- Early Warning System: Detecting temperature fluctuations early helps prevent product spoilage and minimizes the risk of foodborne illnesses.

- Quality Assurance: Consistent monitoring with wall thermometers ensures that frozen fish products maintain optimal conditions from production to consumer purchase, preserving their quality and shelf life.

Implementation and Best Practices

Effective use of wall thermometers requires proper placement in areas where temperature control is critical, such as near refrigeration units, storage room entrances, and transport vehicles. Regular calibration and maintenance are essential to ensure the accuracy of temperature readings and the reliability of monitoring systems.

Regulatory Compliance and Standards

Wall thermometers contribute to compliance with food safety regulations and industry standards. They provide documented evidence of temperature monitoring practices, which is crucial during audits and inspections by regulatory authorities.

.jpg)

.jpg)

.jpg)