Uniform Uses In Fish Processing Plants

By. Najih - 01 Nov 2024

Uniforms in fish processing plants are much more than a simple dress code, they are essential tools for ensuring safety, hygiene, and professionalism in a demanding work environment. By considering factors such as material selection, environmental impact, employee engagement, and cultural sensitivity, fish processing facilities can enhance the effectiveness of their uniform policies. Ultimately, well-designed uniforms contribute to a safer, more efficient, and more cohesive workplace, which is vital for maintaining high standards in fish processing operations.

Here are some of the key uses and considerations regarding uniforms in these facilities:

1. Hygiene and Sanitation

- Prevent Contamination: Uniforms help prevent contamination of the fish products. They are typically made from materials that are easy to clean and sanitize.

-Personal Hygiene: Employees are required to maintain high standards of personal hygiene, and uniforms often include features like hairnets, gloves, and aprons to minimize the risk of contamination.

2. Safety

a. Protective Gear: Uniforms may include protective gear such as steel-toed boots, cut-resistant gloves, and waterproof aprons to protect workers from injuries associated with handling fish and operating machinery.

b. Slip-Resistant Footwear: Given the wet and slippery conditions in processing plants, uniforms often include slip-resistant footwear to reduce the risk of accidents.

3. Identification

a. Role Identification: Different uniforms can signify different roles within the plant, helping to identify employees quickly (e.g., supervisors, quality control personnel, production workers).

b. Branding: Uniforms can also serve as a branding tool, showcasing the company logo and colours, which can enhance brand recognition and professionalism.

4. Comfort and Functionality

1). Ease of Movement: Uniforms are designed to allow for ease of movement, which is crucial in a physically demanding environment where workers may be lifting heavy items or performing repetitive tasks.

2). Temperature Control: Fish processing plants can be cold environments; uniforms may include thermal layers or moisture-wicking fabrics to keep workers comfortable.

5. Compliance with Regulations

Food Safety Standards: Many regions have strict regulations regarding food safety, which include specific uniform requirements for employees in food processing plants. Compliance with these standards is essential to avoid fines and ensure product safety.

6. Training and Awareness

Training Programs: Uniforms can be part of training programs, helping new employees understand the importance of hygiene and safety practices in fish processing.

Promoting Awareness: Wearing uniforms can promote a culture of safety and hygiene among employees, reinforcing the importance of these practices.

.jpg)

The Impact of HACCP-Based Integrated Quality Management Programs on the Quality and Competitiveness of Fresh Demersal Fish Products

and Employee Productivity on the Demersal Fish Processing Floor.jpg)

The Correlation Between Occupational Health and Safety (OHS) and Employee Productivity on the Demersal Fish Processing Floor

Human Resource Management Challenges and Training Needs in Implementing HACCP Quality Standards within the Fish Processing Industry

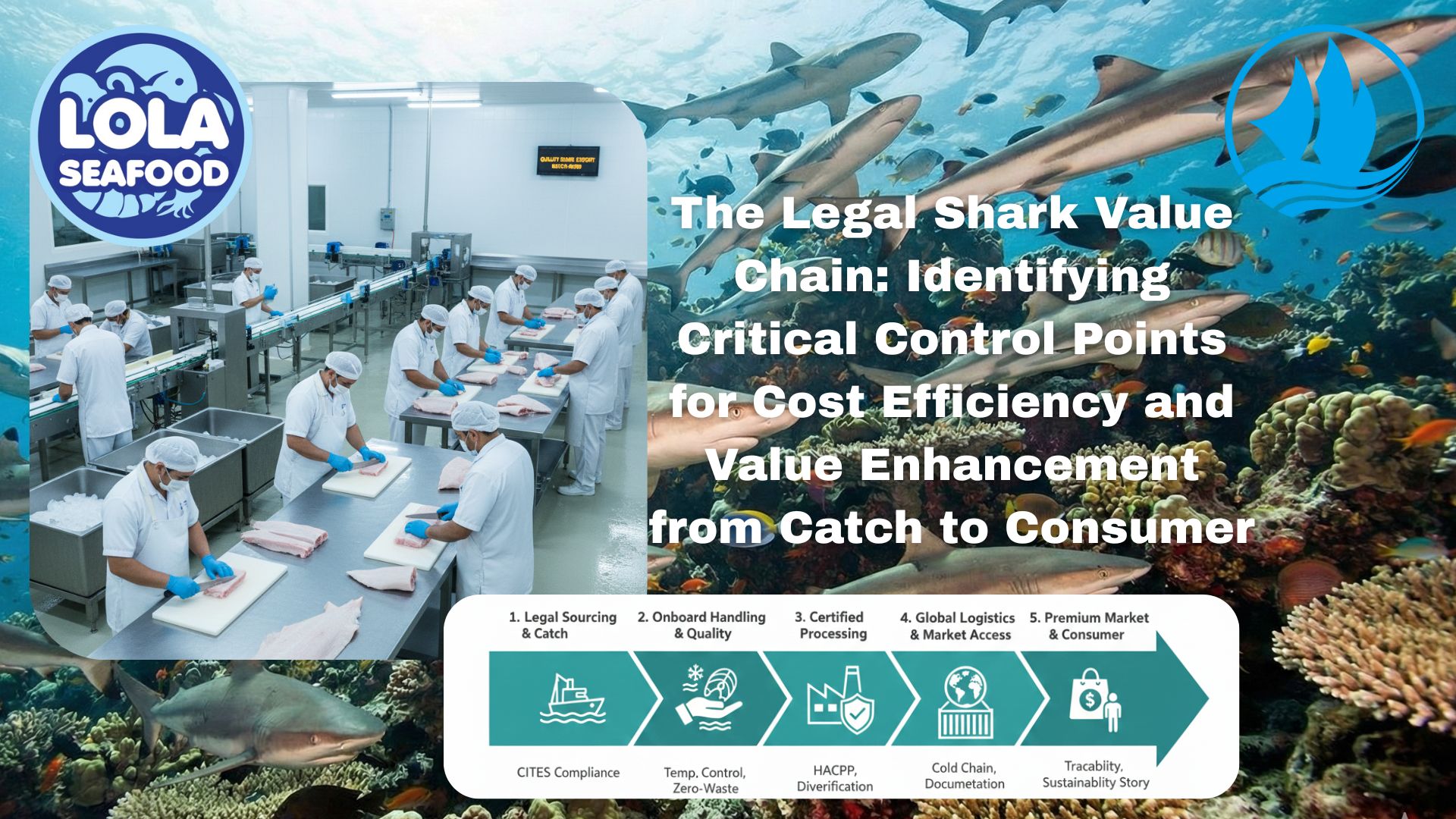

The Legal Shark Value Chain: Identifying Critical Control Points for Cost Efficiency and Value Enhancement from Catch to Consumer

.jpg)

in Meeting Global Protein Demand Sustainably.jpg)