Racking Systems for Cold Storage

By. Najih - 26 Jul 2024.jpg)

Potential hazards Potential hazards that must be controlled in cold storage include bacterial growth, cross contamination, and food beyond date marking. Controls refrigeration slows down bacterial growth and this is why high-risk perishable foods should be kept refrigerated. Hot food must not be placed directly into the refrigerator as it will raise the temperature of the refrigerator above acceptable limits and may cause condensation leading to cross-contamination of food already inside.

Racking systems in cold storage play a vital role in ensuring that products are stored safely and efficiently while maintaining the necessary temperature ranges. The unique challenges of cold storage environments require racking solutions that are robust, durable, and designed to handle extreme conditions.

- Material Selection:

- Corrosion Resistance: Cold storage environments often involve high humidity and low temperatures, which can lead to corrosion.

- Temperature Resilience: Materials used in racking systems must withstand the low temperatures typical of cold storage without becoming brittle or losing strength. This ensures the racks remain safe and functional over time.

- Design Considerations:

- Optimized Airflow: Proper airflow is crucial in maintaining consistent temperatures throughout the cold storage facility. Racking systems should be designed to allow air to circulate freely around stored items, preventing hotspots and ensuring uniform cooling.

- Maximizing Space Utilization: Cold storage is expensive, so maximizing the use of available space is essential. High-density racking solutions, such as mobile racking or double-deep racking, can significantly increase storage capacity without compromising accessibility.

- Safety and Compliance:

- Load Capacity: Racking systems must be capable of supporting the weight of stored items, especially in cold storage where heavy loads are common. Ensuring the racks are properly rated for their intended use is critical for safety.

- Regulatory Compliance: Cold storage facilities must comply with various regulations and standards related to food safety, pharmaceuticals, and other temperature-sensitive goods. Racking systems should be designed to meet these regulatory requirements, ensuring that the facility operates within legal guidelines.

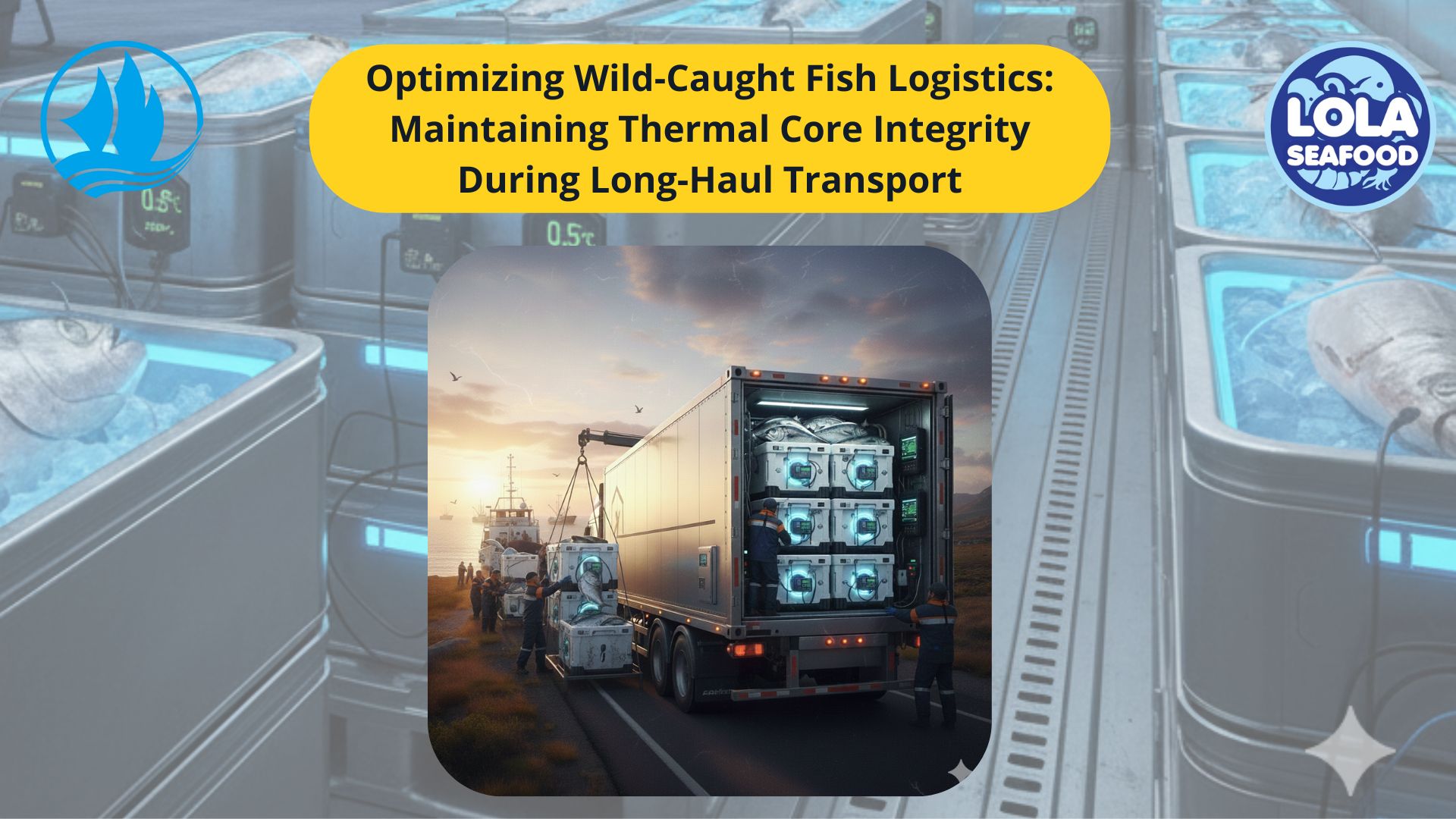

Optimizing Wild-Caught Fish Logistics: Maintaining Thermal Core Integrity During Long-Haul Transport

.jpg)

.jpg)

and Employee Productivity on the Demersal Fish Processing Floor.jpg)