The Art and Science of Processing Baby Octopus

By. Fajar - 10 Feb 2026

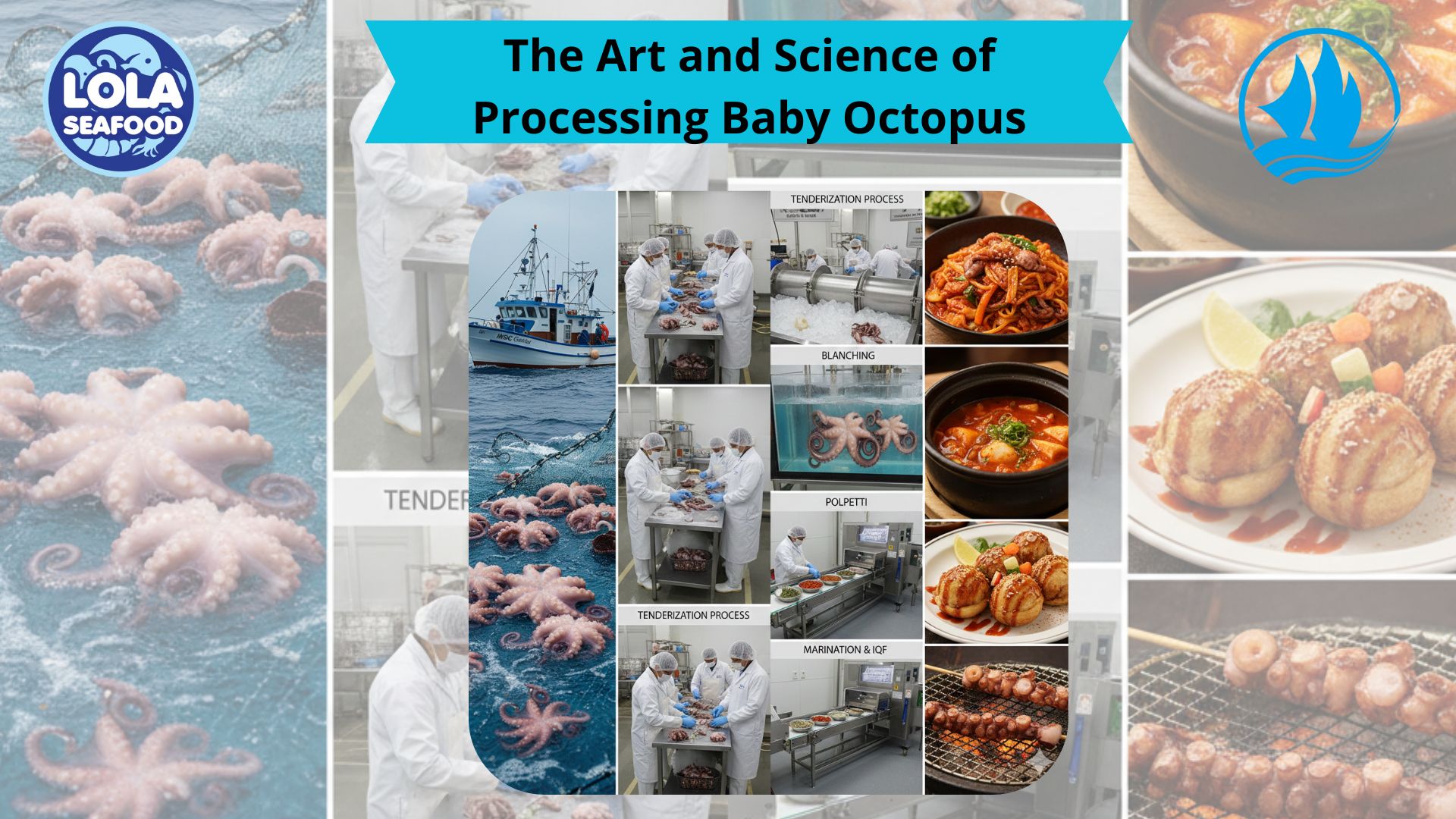

kelolalaut.com The culinary world has a fascination with the "baby" versions of seafood, and the baby octopus is no exception. Prized for its tender texture, aesthetic appeal, and ability to absorb bold flavors, this cephalopod is a staple in Mediterranean, East Asian, and Southeast Asian cuisines. However, transforming a fresh-caught baby octopus into a gourmet dish requires a delicate balance of traditional techniques and modern food safety standards.

Understanding the Source

While the term "baby octopus" suggests a juvenile, most of what we consume are actually adult specimens of smaller species, such as the Octopus membranaceus. These creatures are primarily harvested in the warm waters of the Western Pacific and the Indian Ocean. Because they are highly perishable, the processing journey—from the fishing vessel to the kitchen—is a race against time.

Step 1: Cleaning and Preparation

The first and most critical stage of processing is cleaning. Unlike larger octopuses that can be tough and fibrous, baby octopuses are delicate.

- Defrosting: If starting from frozen, the octopus must be thawed slowly in a refrigerator or under cold running water to maintain its structural integrity.

- The "Inards" Removal: The head (mantle) is turned inside out to remove the stomach, ink sac, and internal organs. While the ink is a delicacy in some cultures, it is usually removed during mass processing to prevent staining the meat.

- The Beak and Eyes: The "beak"—a hard, parrot-like mouthpart located at the center of the tentacles—is popped out. The eyes are then carefully snipped away.

- Tumbling: In commercial processing, baby octopuses often undergo "tumbling" in large rotating drums with salt and ice. This removes the natural slime and begins the tenderization process without damaging the skin.

Step 2: The Secret to Tenderness

The biggest challenge with any octopus is avoiding a rubbery texture. Octopus meat is rich in collagen, a structural protein that makes the flesh tough if not handled correctly.

In traditional Mediterranean processing, fishermen would beat the octopus against rocks. In a modern setting, we use science. To achieve a "melt-in-the-mouth" feel, the octopus is often blanched. This involves dipping the octopus into boiling water for a few seconds until the tentacles curl into beautiful spirals, then immediately shocking it in an ice bath.

For baby octopus, the cooking time is significantly shorter than its larger cousins. While a large octopus might need an hour of simmering, a baby octopus can become tender in just 5 to 10 minutes of poaching or a quick 2 to 3 minutes on a high-heat grill.

Step 3: Preservation and Value-Adding

Processed baby octopus is rarely sold "plain" in the global market. To add value, processors often engage in:

- Marination: Infusing the meat with garlic, lemon, oregano, or spicy gochujang.

- Pre-cooking: Many frozen packs are "RTE" (Ready to Eat) or "RTC" (Ready to Cook), having been steamed to the perfect internal temperature before freezing.

- Individual Quick Freezing (IQF): This technology ensures that each octopus is frozen separately, preventing them from clumping together and preserving the cell structure.

Culinary Applications: A Global Palette

Once processed, the baby octopus becomes a versatile canvas for chefs:

- In Korea (Nakji-bokkeum): It is stir-fried in a fiery red pepper sauce, served over rice or noodles.

- In Italy (Polpetti): It is slow-simmered in a rich tomato and red wine sauce until the sauce thickens and the octopus is buttery soft.

- In Japan (Takoyaki/Iidako Sushi): It is either encased in savory batter balls or served whole as a visually stunning nigiri topping.

- In Greece: It is marinated in vinegar and olive oil, then charred over charcoal to create a smoky, crisp exterior.

Sustainability and Quality Control

As demand for baby octopus grows, sustainability has become a focal point of processing. Ethical processors now adhere to MSC (Marine Stewardship Council) guidelines to ensure that harvesting doesn't deplete local populations. Quality control involves rigorous testing for heavy metals and ensuring that the "glazing" (the ice coating on frozen seafood) does not exceed 10–20% of the total weight, ensuring consumers get what they pay for.

If youre interested in our Baby Octopus Flower, Baby Octopus Whole Cleaned, Baby Octopus Whole Roundplease do not hesitate to contact us through email and/or Whatsapp

in Modern Fish Processing Industries.jpg)