The Art and Science of Fish Defrosting in the Industrial Processing Sector

By. Ely Kusniawati - 05 Feb 2026

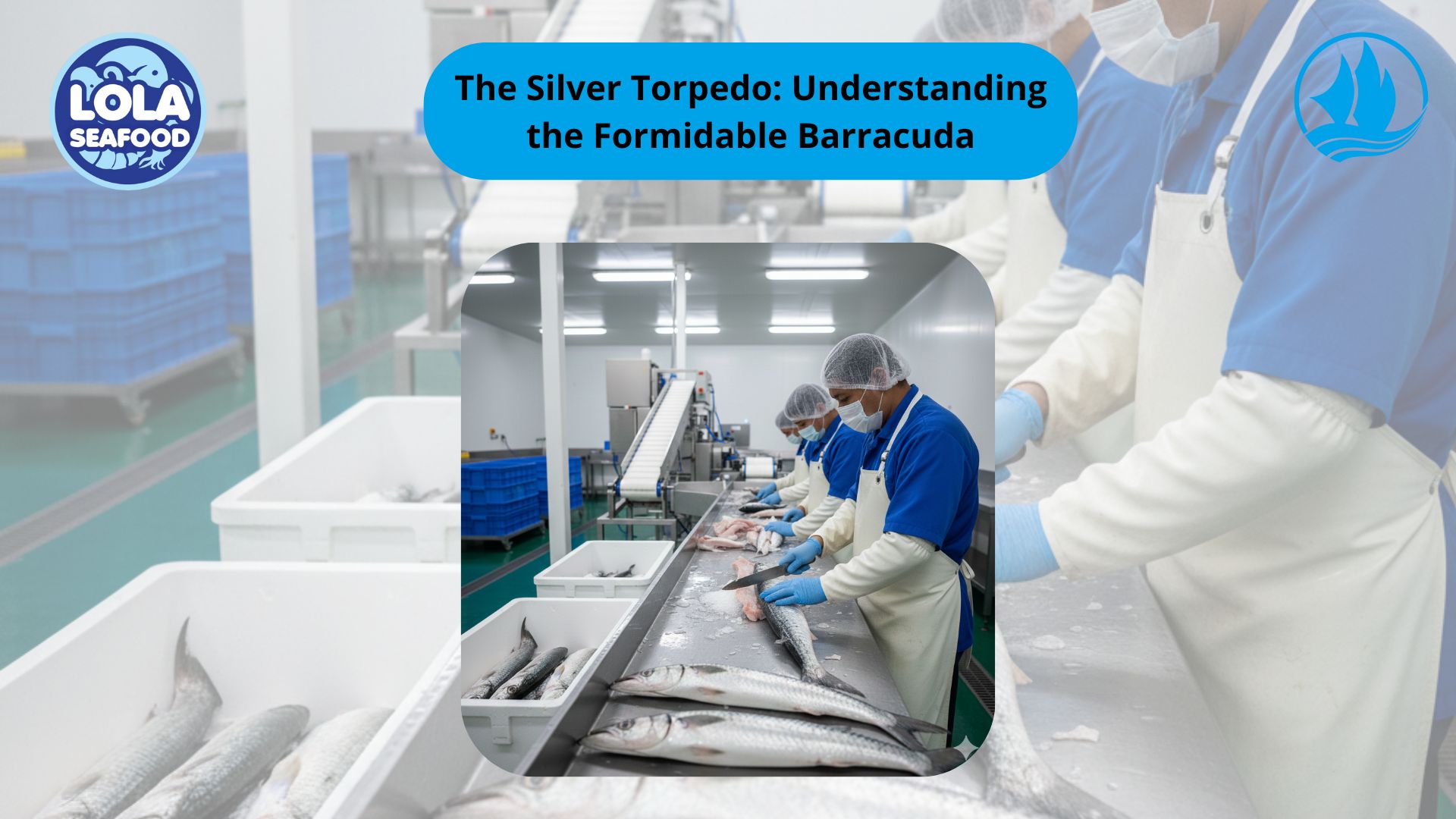

kelolalaut.com In the global seafood supply chain, freezing is the primary method used to preserve quality, extend shelf life, and ensure a steady supply of fish throughout the year. However, the transition from a frozen state back to a processable raw material—known as defrosting or thawing—is perhaps the most critical stage in industrial fish processing.

While it might seem as simple as "letting the ice melt," improper thawing can lead to significant economic losses, safety hazards, and a finished product that tastes like cardboard. In a high-stakes industrial environment, the goal is to minimize drip loss, prevent bacterial growth, and maintain the structural integrity of the muscle tissue.

The Challenge: Cellular Integrity and Drip Loss

To understand why defrosting is difficult, we have to look at the biology of the fish. Fish muscle has a high water content. When fish are frozen, this water turns into ice crystals. If the freezing process was slow, these crystals are large and jagged, puncturing cell membranes.

During thawing, the goal is to reabsorb that moisture into the muscle fibers. If the thawing process is too fast or uneven, the water simply leaks out—a phenomenon known as drip loss. This isn't just water; it’s a cocktail of proteins, vitamins, and minerals. High drip loss results in:

- Reduced Yield: The fish literally loses weight, which translates directly to lost revenue.

- Textural Degradation: The meat becomes dry, tough, or "spongy."

- Loss of Flavor: The essential nutrients and salts that give fish its profile are washed away.

Industrial Defrosting Methods

Modern processing plants use several sophisticated methods to thaw fish, each balanced between speed, cost, and quality.

1. Air Thawing (Still or Forced)

This is the most traditional method. Fish are placed in a room where controlled air circulates around them.

- Pros: Low equipment cost.

- Cons: Very slow. If the air is too warm, the surface of the fish enters the "danger zone" (where bacteria thrive) while the center remains frozen. To combat this, processors use High-Humidity Air Thawing, which uses moist air to prevent the fish from drying out.

2. Water Thawing (Immersion or Spray)

Water conducts heat roughly 20 times faster than air.

- Static Immersion: Fish are placed in tanks of still water.

- Circulating Water: Water moves constantly, ensuring a consistent temperature.

- The Risk: Using too much water can lead to environmental concerns and water waste. Additionally, if the water isn't chilled (usually kept between 10°C and 15°C), the fish can lose its "bloom" or fresh appearance.

3. Vacuum Thawing

This method uses the latent heat of steam under vacuum conditions. Because the boiling point of water is lower in a vacuum, the fish can be "steamed" at very low temperatures (e.g., 20°C).

- Benefit: It provides incredibly rapid and uniform thawing without the risk of "cooking" the exterior.

4. Acoustic and Radio Frequency (RF) Thawing

The cutting edge of the industry involves electromagnetic waves. RF Thawing generates heat within the fish itself by vibrating water molecules (similar to a microwave but much more controlled and at lower frequencies).

- The Advantage: It can thaw a block of fish in minutes rather than hours, significantly reducing the time available for bacterial growth.

Quality Control and Safety Standards

In an industrial setting, defrosting is governed by strict HACCP (Hazard Analysis and Critical Control Points) protocols. The "Danger Zone"—the temperature range between 5°C and 60°C—is the enemy.

To ensure safety, processors must monitor:

- Surface Temperature: Ensuring the skin doesn't get warm enough to allow Listeria or Salmonella to bloom.

- Internal Temperature: Ensuring the core has reached the target temperature (usually around -1°C to 2°C) for easy filleting or canning.

- Hygiene: Tanks and air units must be sanitized daily to prevent cross-contamination.

The Economic Impact

For a large-scale cannery or filleting plant processing 50 tons of tuna or salmon a day, a 1% reduction in drip loss can save hundreds of thousands of dollars annually. Efficient defrosting also dictates the workflow of the entire plant. If the thawing is inconsistent, the automated skinning and deboning machines will fail, leading to more manual labor and further waste.

If youre interested in our Snapper / Red Bass Whole Round / Whole Gilled Gutted Scaled , Snapper Fillet Skinless and Snapper Mangrove Jack Whole Round / Whole Gilled Gutted Scaled, Barramundi Fillet Skinless please do not hesitate to contact us through email and/or Whatsapp

The Deep-Sea Treasure of High-Quality Protein.jpg)