The Critical Pulse: Why Routine Temperature Maintenance is the Backbone of Fish Processing

By. Sofie Thoriq - 20 Feb 2026

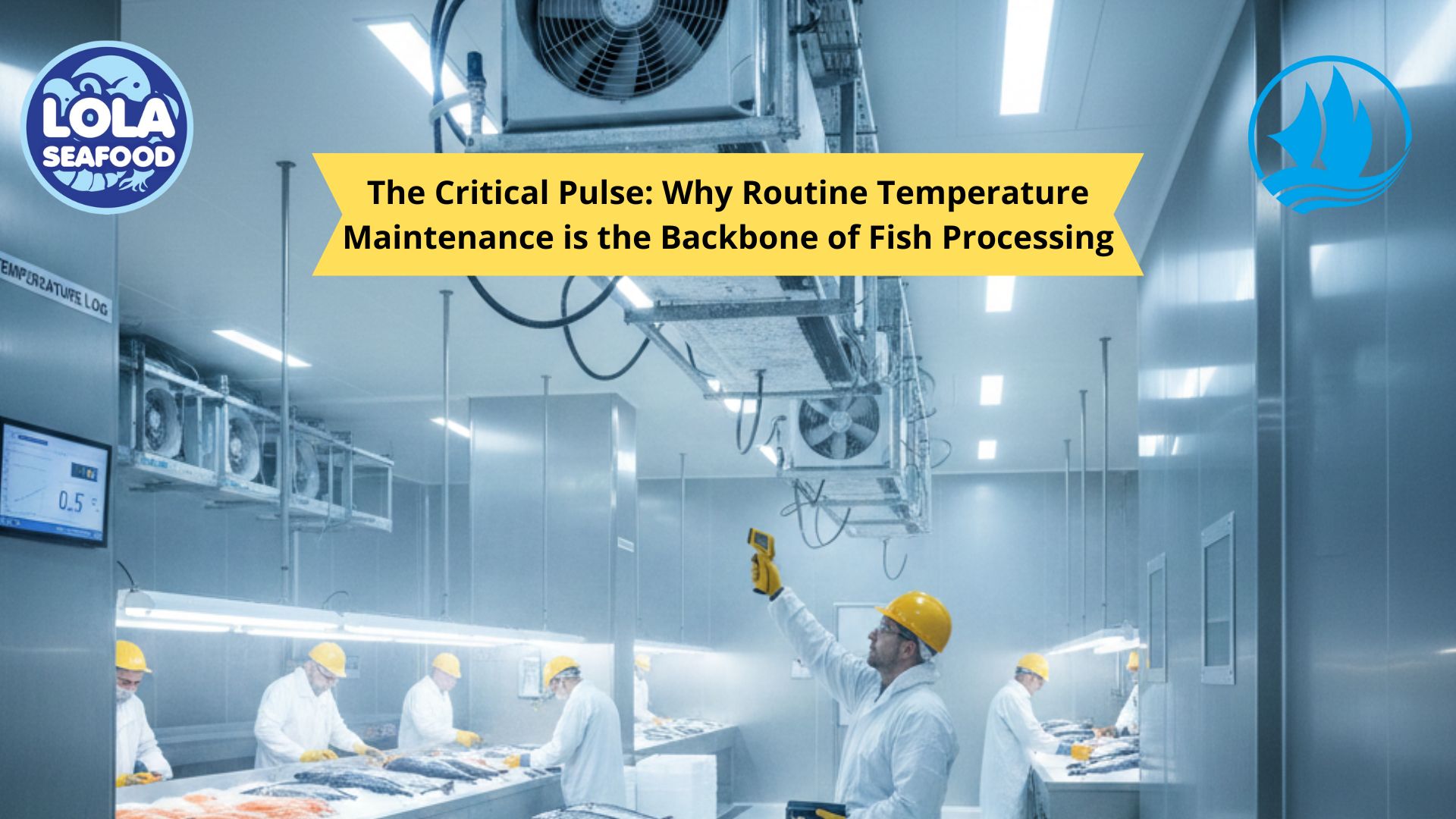

kelolalaut.com In the global food industry, few sectors are as demanding or as volatile as fish processing. From the moment a fish is hauled from the ocean to the second it reaches a consumer’s plate, it is in a race against time and biology. In this high-stakes environment, temperature control is not just a technical requirement—it is the pulse of the entire operation. Failing to perform periodic maintenance on temperature systems is not merely a technical oversight; it is a direct threat to public health, brand reputation, and financial viability.

The Biological Reality: Why Fish are Different

Unlike terrestrial livestock, fish are generally cold-blooded organisms adapted to cold aquatic environments. Their metabolic enzymes and the bacteria naturally present on their skin and in their guts remain active even at low temperatures.

When ambient room temperatures in a processing facility drift even a few degrees above the required threshold—typically maintained near 0°C to 4°C for fresh processing—microbial growth doesn't just increase; it explodes. Pathogens like Listeria monocytogenes and Vibrio can thrive, leading to foodborne illnesses. Regular maintenance ensures that sensors and cooling units are calibrated to prevent these "microbial windows" from opening.

1. Preserving Sensory Quality and Market Value

The economic value of fish is tied directly to its freshness, measured by texture, odor, and color.

- Protein Degradation: High or fluctuating temperatures trigger proteolysis, where enzymes break down fish muscle, leading to "gaping" or mushy meat.

- Lipid Oxidation: Fish high in omega-3 fatty acids, like salmon or mackerel, are prone to rancidity if temperatures aren't strictly controlled.

Periodic maintenance of HVAC and refrigeration systems prevents "temperature spikes" that occur when a system struggles to recover after doors are opened or when new stock is introduced. A well-maintained system provides the thermal stability necessary to keep premium products at premium prices.

2. Preventing Chemical Hazards: The Histamine Risk

In certain species—specifically scombroid fish like tuna, mackerel, and skipjack—temperature abuse leads to the formation of histamine. Unlike bacteria, histamine is heat-stable; once it forms due to poor temperature control during processing, cooking or canning will not remove it.

This can lead to Scombroid Poisoning in consumers. Regulatory bodies like the FDA and the EU have zero-tolerance or very low-threshold policies for histamine. Routine maintenance of cooling coils and thermostats is the only way to guarantee that the "Cold Chain" remains unbroken, mitigating the risk of massive product recalls and legal liabilities.

3. Operational Efficiency and Energy Conservation

Fish processing plants are energy-intensive environments. Refrigeration can account for up to 60-70% of a facility's total energy consumption.

- The Cost of Neglect: A layer of ice just 3mm thick on an evaporator coil can increase energy consumption by 10-15%.

- Preventative vs. Reactive: Routine checks on refrigerant levels, compressor health, and door seals prevent the system from "overworking." An overworking system not only burns more electricity but is also prone to catastrophic failure.

By investing in periodic maintenance, companies transition from a "fix-it-when-it-breaks" mentality—which usually involves expensive emergency repairs and lost inventory—to a streamlined, cost-effective operational model.

4. Regulatory Compliance and the Digital Trail

Modern fish processing operates under the HACCP (Hazard Analysis Critical Control Point) framework. Temperature is almost always a "Critical Control Point" (CCP).

During audits, inspectors don't just look at the fish; they look at the logs. If a temperature sensor is out of calibration or a cooling unit has a history of unaddressed fluctuations, the facility risks losing its certification. Regular maintenance provides the documented proof of due diligence required for international export, ensuring that the facility meets the standards of the Global Food Safety Initiative (GFSI).

Key Maintenance Focus Areas

To ensure a robust cooling environment, the maintenance schedule should focus on:

- Sensor Calibration: Ensuring the digital readout matches the actual physical temperature.

- Structural Integrity: Checking thermal strips and door gaskets to prevent "cold air bleeding."

- Airflow Optimization: Cleaning fans and clearing obstructions to ensure uniform cooling across the entire processing floor.

If youre interested in our Whiting Fish Whole Round,Barramundi Fillet Skin On,Catfish Fillet Skinless,Cobia Fillet Skinless,Coral Trout Fillet Skin On,Barramundi Whole Round / Whole Gilled Gutted Scaled,Corvina / Croaker / Jew Fish Whole Round / Whole Gilled Gutted Scaled,Black Pomfret Whole Round,Red / Scarlet Snapper Fillet Portion,Parrotfish Fillet Skinless,Baby Octopus Flower please do not hesitate to contact us through email and/or Whatsapp