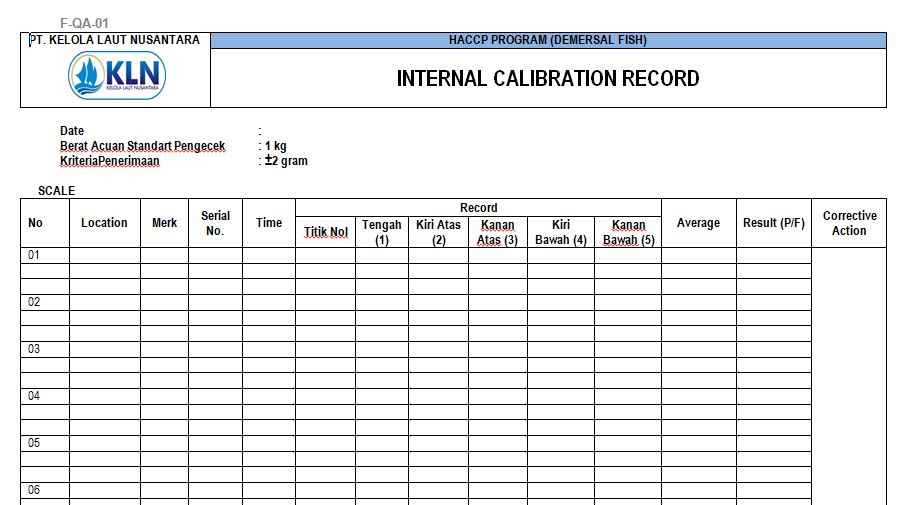

SCALE CALIBRATION

By. Najih - 25 Aug 2023

kelolalaut.com - Calibration is the process of verifying a weighing scale’s accuracy by conducting extensive testing and comparing the data obtained with a known and accepted standard. This system allows for any problems with data outputted by a scale to be identified and, ultimately, rectified. In simple terms, calibration is a quantitative comparison. The error is defined as the difference between the measured value (the reading) and the true value (the reference weight). The accuracy of all scales will slowly degrade as a result of continuous use over time; electrical overloads, changes in climate, accidents, and other events can all be detrimental to the performance of a weighing scale and can eventually lead to inadequate readings being displayed on measuring devices.

Scale calibration is essential to achieve accurate weighing results. Ignoring this important service activity turns measuring into guesswork. Calibration, performed by an authorized provider offers the following benefits:

- Cost savings. Calibrated equipment allows sound decision-making, which avoids waste, rework, or product recall.

- Reliable measurements. Using calibrated equipment assures that measurements made in one place are compatible with those made in another. Results from any balance in the process will be accurate and reliable, as will the final product.

- Compliance. Calibration facilitates the smooth passing of internal and external audits.

- Detection of aging equipment. All equipment ages over time and critical components may sustain mechanical stress or wear and tear. Drift cannot always be eliminated but it can be detected through periodic calibration.

- Process and profit improvement. Interpretation of calibration results according to defined tolerances improves processes and ultimately increases profit.

A calibration certificate reports results at the time the calibration was performed. In many cases, the responsible person assumes that the calibration is valid for a year. This leads to the wrong conclusion that a calibration interval of one year is sufficient. Calibration intervals are defined following a risk-based methodology, for example, what is the probability of something going wrong, and how high is the impact? A high impact and high probability corresponds to a high risk, which requires a shorter calibration interval. Otherwise, a low impact and a low probability results in a low risk, allowing intervals to be extended.