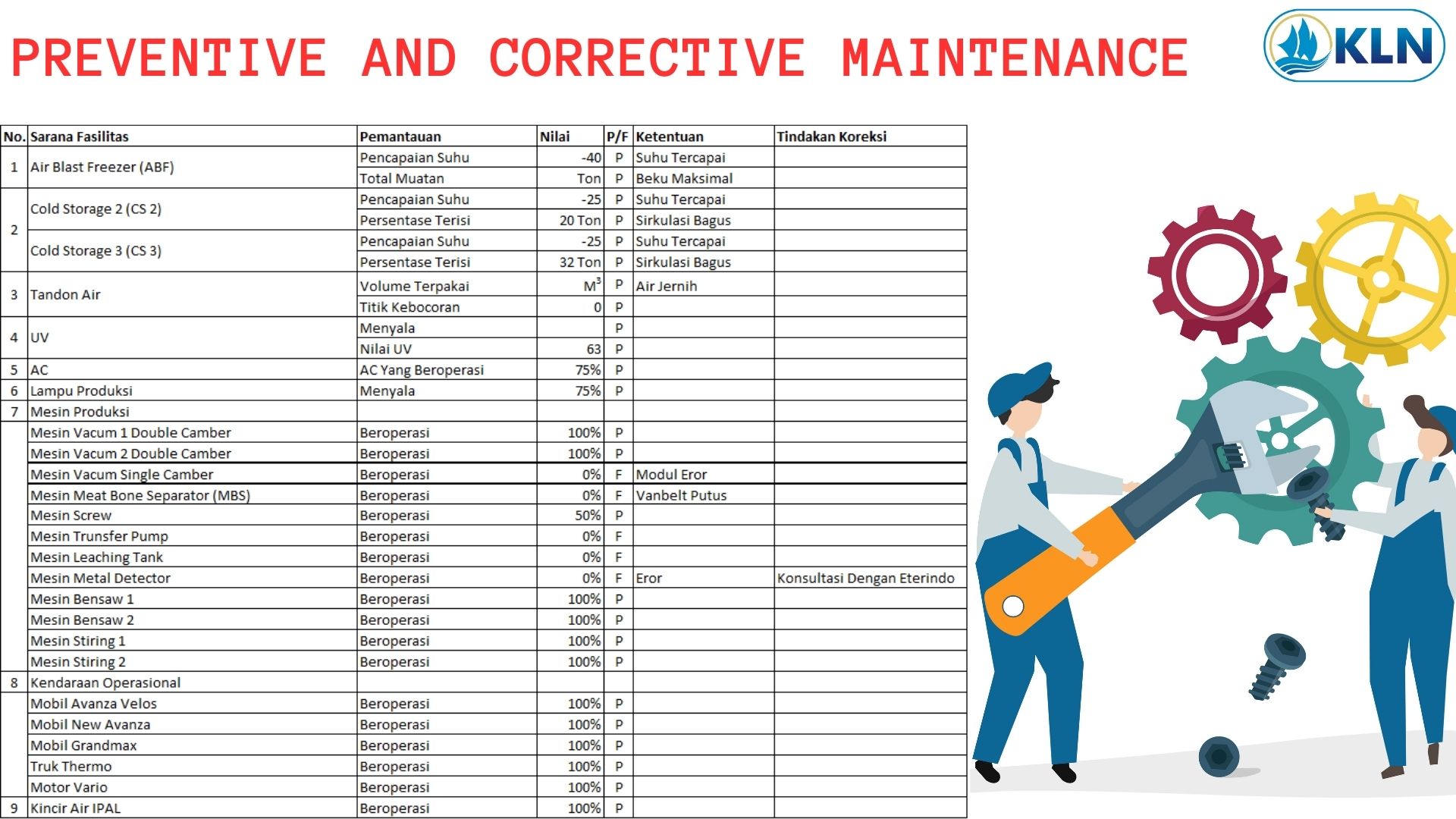

PREVENTIVE AND CORRECTIVE MAINTENANCE

By. Najih - 04 Oct 2023

Corrective maintenance is done after sudden asset failure and preventive maintenance avoids sudden failure. A written preventive maintenance programme shall be established to ensure proper preventive maintenance of all equipment and of relevant areas of the facility. The preventive maintenance programme should include:

– A procedure to ensure the proper cleaning and sanitizing of equipment after maintenance activity, before it is used in product processing

– Notification to sanitation crew by production personnel of the need for cleaning and sanitizing after maintenance work is completed

– A procedure for reconciling parts and tools after maintenance is performed. All parts and tools must be accounted for (by checking against a list to ensure all parts and tools are reconciled)

– Verification and sign-off by designated personnel (operations staff, production staff or quality staff taking the responsibility from maintenance staff) that food contact zones have been cleared of any parts and tools before being released to production. Management must be notified immediately if any parts, tools or pieces of equipment are found to be missing. Corrective action(s) are documented. No loose or unaccounted-for parts or tools are found in the processing areas.

– A procedure to protect exposed and non-exposed products during maintenance activities is documented.

– Guidelines must be in place to remove products known to have been contaminated by any missing parts or tools, to prevent their entrance into the final product.

– Records that must be available to review: Records of equipment parts and tools reconciliation checklist following maintenance activities (before and after); Records of notification to sanitation crew of cleaning and sanitizing required after maintenance work is completed; Records of food contact zones that have been cleaned and sanitized before being released to production; Records of corrective actions.

Corrective Maintenance

Equipment and structure repairs shall be properly completed. The corrective maintenance system must ensure:

– All equipment and structures are properly maintained.

– Equipment repairs or modifications are professionally completed without the use of string, tape, wire or other improvised materials.

– Should temporary repair be required to complete the shift’s production run, the temporary repair does not pose any risk to food safety. Permanent repair should be completed within one month or as early as possible.

– If a repair must be completed during production time, preventive measures are taken to prevent product contamination.