Step by Step Fish Processing for Ensuring Top Quality

By. Najih - 13 Sep 2024

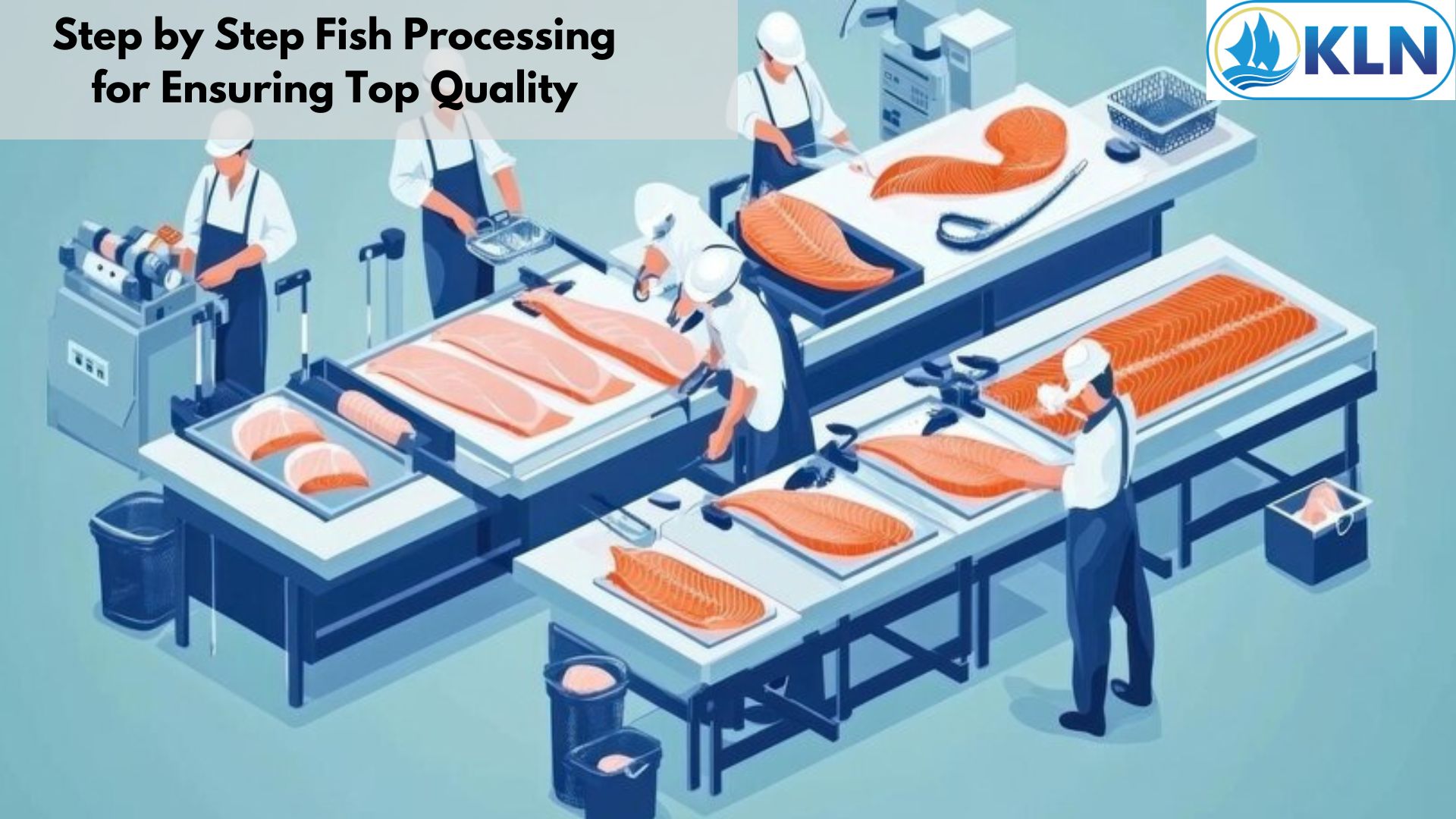

Ensuring top quality in fish processing involves a meticulous step-by-step approach, designed to preserve freshness, taste, and safety. This article outlines the essential stages of fish processing that collectively contribute to delivering high-quality seafood products.

1. Catching and Immediate Handling

The processing journey starts with the catch. Proper handling immediately after capture is crucial for maintaining fish quality. Fishermen use techniques that minimize stress and physical damage, such as specialized nets and quick chilling methods. Cooling the fish rapidly with ice or refrigerated water slows down metabolic processes and prevents spoilage.

2. Sorting and Grading

After initial handling, fish are sorted and graded. Sorting involves categorizing fish by species, size, and quality, ensuring that only the best fish proceed to the next stages. Fish that do not meet quality standards are either discarded or redirected for other uses. Grading helps in determining appropriate processing methods and pricing, ensuring that high-quality fish are treated accordingly.

3. Cleaning and Evisceration

Cleaning and evisceration are crucial steps to prevent contamination and extend shelf life. This process involves removing internal organs, blood, and any other impurities from the fish. Effective cleaning removes contaminants, while evisceration eliminates organs that could contribute to spoilage if left inside. This step is vital for maintaining the quality and safety of the fish.

4. Filleting and Portioning

Once cleaned, the fish are filleted and portioned. Filleting involves removing bones and skin to produce boneless, skinless fillets. Precision is required to maximize yield and minimize waste. The fillets are then portioned into sizes suitable for different market segments, such as retail or food service, catering to various consumer needs.

5. Freezing and Storage

To preserve freshness, fish are often frozen shortly after processing. Freezing halts bacterial growth and maintains the fish’s texture and flavor. Blast freezing is typically used to ensure even freezing, which helps in retaining high quality. Proper storage conditions are crucial to prevent freezer burn and maintain the product's integrity.

6. Packaging and Distribution

The final stage involves packaging and distribution. Fish fillets are packed in vacuum-sealed bags or other suitable materials to prevent contamination. Efficient distribution ensures that the fish reaches the market in optimal condition, maintaining the cold chain throughout the process.