Maximizing Efficiency and Quality with Skinless Fish Processing

By. Najih - 23 Sep 2024

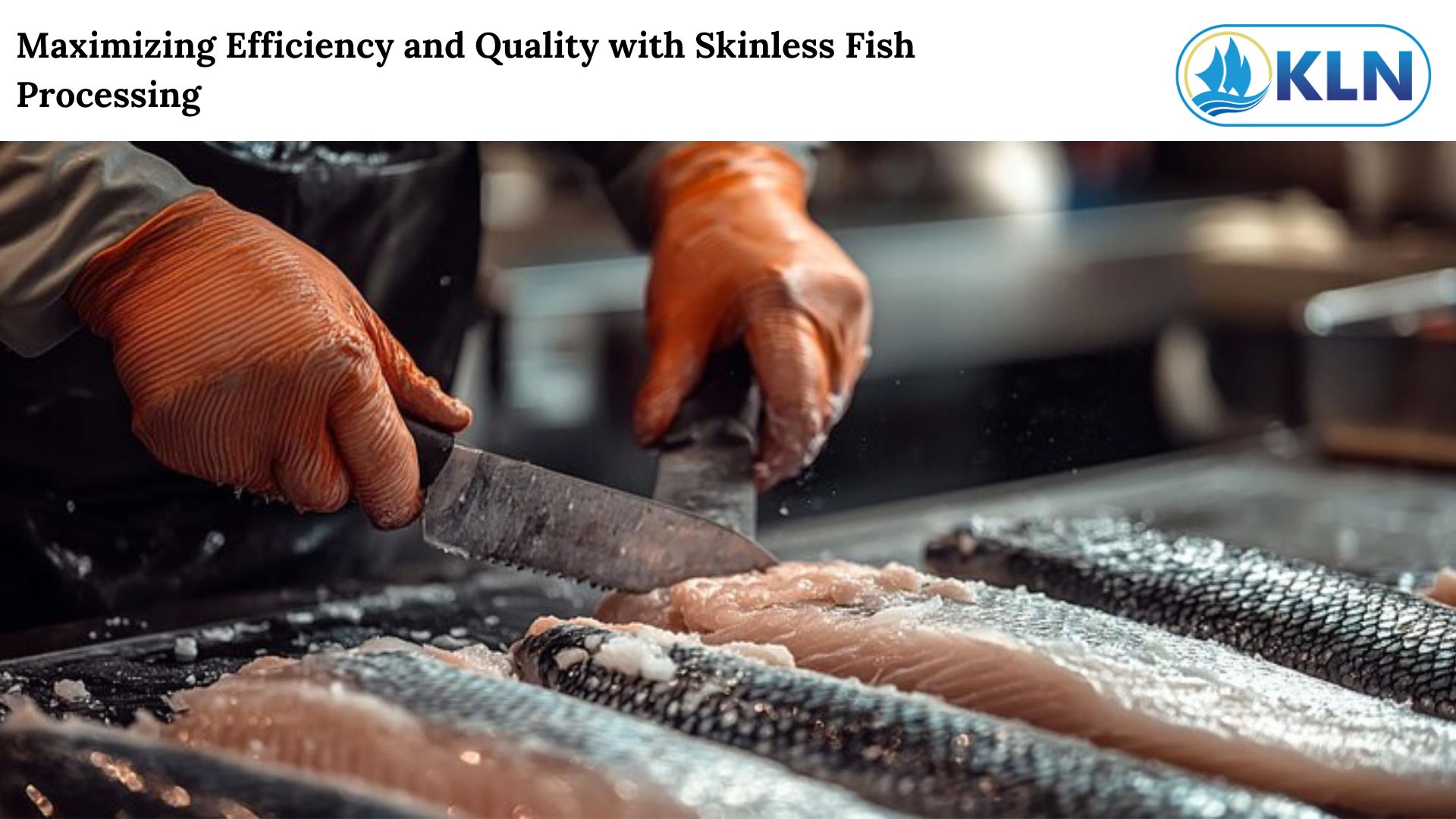

Skinless fish processing is a key technique in the seafood industry that enhances product quality and operational efficiency. By removing the skin from fish, this method offers several benefits that cater to both producers and consumers. In this article, we will explore the advantages of skinless fish processing and how it contributes to a more efficient and high-quality seafood operation.

What is Skinless Fish Processing?

Skinless fish processing involves removing the skin from fish fillets or steaks. This technique is commonly used in the seafood industry to produce a clean, uniform product that meets specific market demands. Skinless fish is often preferred for its versatility and appeal in various culinary applications.

Benefits of Skinless Fish Processing

- Enhanced Product Uniformity

Skinless fish processing results in a more consistent and visually appealing product. Removing the skin ensures uniformity in size and shape, which is crucial for presentation and cooking consistency.

- Improved Cooking Versatility

Without the skin, fish fillets are easier to prepare and cook using various methods. Skinless fish is ideal for dishes that require even cooking, such as pan-searing, baking, or poaching, and allows for a wider range of culinary applications.

- Increased Yield

Skinless processing can lead to a higher yield of usable fish meat, as there is no loss associated with skin removal during cooking. This increased yield contributes to better utilization of the fish and reduced waste.

- Enhanced Safety and Hygiene

Skinless fish processing minimizes the risk of contaminants that may be present on the skin. This method promotes better hygiene and safety standards, as the skin can harbor bacteria or parasites that are removed during processing.

- Consumer Preference

Many consumers prefer skinless fish for its convenience and aesthetic appeal. Skinless fillets are often considered more convenient for meal preparation and are favored in pre-packaged seafood products.

Applications of Skinless Fish Processing

Skinless fish processing is widely used in various seafood products, including:

- Fillets: Perfect for quick cooking methods and versatile recipes.

- Steaks: Ideal for dishes requiring uniform cooking and presentation.

- Pre-Packaged Products: Common in retail and foodservice products where skinless fish is a market preference.