From Sea to Scampi: The Industrial Processing of Whiting Fish

By. Nugroho Luhur - 06 Feb 2026

kelolalaut.com In the hierarchy of commercial seafood, the whiting (Silago Sihama) has long played a supporting role to titans like Cod and Pollock. However, in the modern food industry, whiting is a protagonist in its own right. Valued for its clean, snowy-white flesh and its ability to absorb flavors, it is the backbone of many "scampi-style" products and breaded fillets found in global supermarkets. Yet, because its flesh is significantly more delicate than other whitefish, the industrial processing of whiting is a sophisticated race against time and temperature.

The Cold Chain: Harvesting and Immediate Preservation

The journey begins in the cold waters of the North Atlantic or the Mediterranean. The moment a whiting is hauled aboard a commercial trawler, the "quality clock" starts ticking. Unlike the firm muscle structure of a Halibut, whiting contains active enzymes that can soften the meat rapidly after death.

To combat this, industrial vessels utilize Refigerated Sea Water (RSW) systems or slurry ice. By submersing the catch in a mixture of seawater and crushed ice, the fish's core temperature is brought down to near 0°C almost instantly. This rapid cooling suspends enzymatic degradation and ensures that when the fish reaches the shore-based processing plant, the fillet remains firm enough for mechanical handling.

Primary Processing: The High-Tech Factory Floor

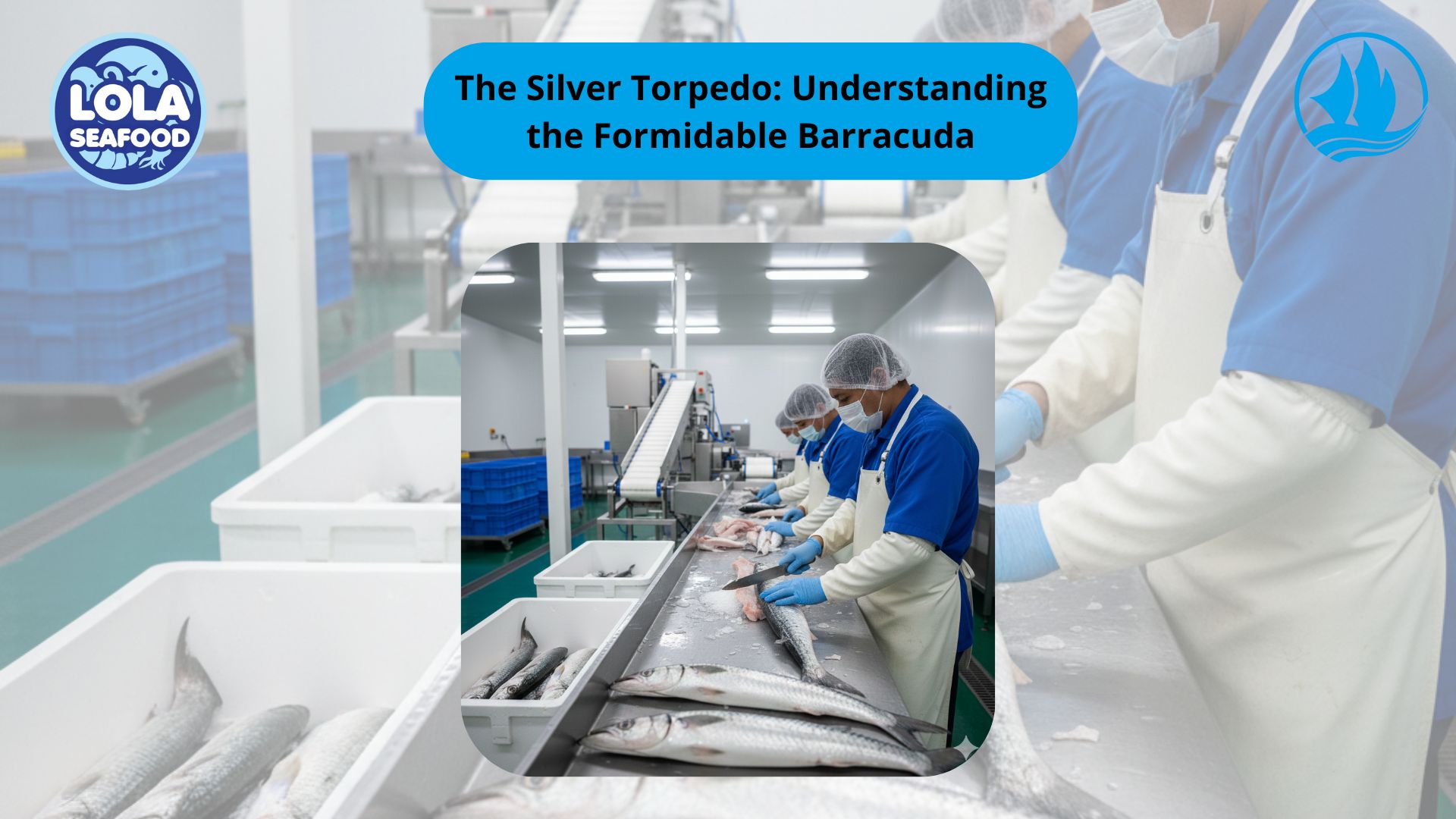

Once the catch is offloaded, it enters a highly automated environment designed for speed and hygiene. The goal of primary processing is to transform a whole fish into a clean, skinless fillet with minimal waste.

- Automated Sorting and Grading: Computer vision systems use cameras to scan each fish as it moves along a conveyor belt. The system measures the length and girth of the whiting, automatically diverting it to specific processing lines optimized for its size. This ensures that the mechanical blades in the next steps are calibrated perfectly for the fish’s anatomy.

- Heading and Gutting (H&G): Precision is the priority here. Modern heading machines use a "V-cut" or "round cut" to remove the head while preserving the "cheeks" and shoulder meat, which are high-yield areas. Vacuum-assisted gutting systems then remove internal organs cleanly, preventing any visceral fluids from staining or tainting the delicate white flesh.

- Mechanical Filleting: This is where the whiting’s fragility poses the biggest challenge. The filleting machine uses high-speed circular blades to strip the meat from the backbone. Because whiting bones are relatively soft, the machines must be tuned with extreme accuracy to avoid "shattering" the bone or leaving excess ribbon meat on the skeleton.

Secondary Processing: Refining the Product

For whiting destined to become "Scampi" or premium fillets, secondary processing is where the value is added.

- Pin-Bone Removal: Whiting contain a row of small, intramuscular bones known as pin-bones. In premium processing, these are removed using an automated "V-cut" machine that carves out a thin strip of flesh containing the bones. Alternatively, high-end facilities use sensor-guided water jets to precision-cut the bones out, minimizing meat loss.

- Skinning: Most industrial whiting products are sold skinless. A skinning machine uses a pressurized roller and a stationary blade to "peel" the skin. A key indicator of quality is whether the "silver-skin" (the thin, iridescent membrane) remains on the fillet; this membrane helps hold the delicate flake together during the cooking process.

Preservation: The Power of IQF

Because whiting has a high water content, traditional bulk freezing would turn the meat into a mushy texture upon thawing. The industry solution is Individually Quick Frozen (IQF) technology.

Fillets are spread out on a mesh belt and passed through a cryogenic tunnel where they are blasted with liquid nitrogen or extremely cold air. This freezes the moisture inside the cells so quickly that large ice crystals—which would normally rupture the cell walls—cannot form. The result is a frozen fillet that, when thawed, retains the texture of a fresh catch. After freezing, a fine mist of water is sprayed over the fish to create an "ice glaze," acting as a protective barrier against oxygen and freezer burn.

From Waste to Value: The Circular Economy

The industrial processing of whiting is remarkably efficient. The "yield" of a fillet is typically about 35%-40% of the fish's total weight. In modern plants, the remaining 60% (heads, bones, and skin) is not discarded. These by-products are processed into high-protein fish meal for aquaculture or refined into fish oils rich in Omega-3. This "zero-waste" approach ensures that the whiting industry remains both economically viable and environmentally responsible.

If youre interested in our Whiting Fish Whole Round please do not hesitate to contact us through email and/or Whatsapp